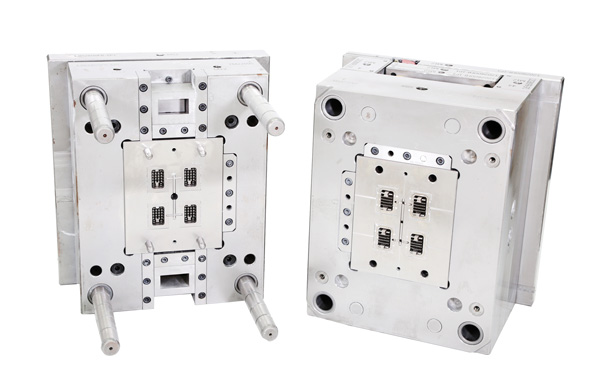

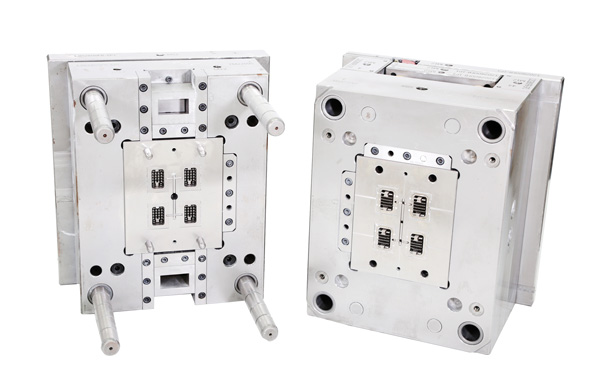

The plastic products we see in our daily lives are all the result of injection molding factories injecting plastic raw materials into molds. Molds, the "invisible champions" of the manufacturing industry, play a pivotal role in multiple sectors. Based on their molding characteristics, molds can be divided into thermoset plastic molds and thermoplastic plastic molds. So, what are the unique features of injection molding factories? The injection molding process involves injecting molten material into a mold cavity under high pressure, and after it cools and solidifies, we obtain the desired molded product.

-

Wide Range of Applications, Creating Infinite Possibilities

Injection molds have a wide range of applications. They can simultaneously form plastic parts with complex structures, precise dimensions, and good internal quality. Therefore, injection molds are ubiquitous in the production of plastic products.

-

Stringent Precision Requirements, Ensuring Excellent Quality

The design and manufacture of injection molds, as well as the reasonableness of their geometric shapes and structural dimensions, directly affect the rheological properties and filling effect of polymer melts in the mold channels, ultimately impacting the molding quality of plastic parts. Precision is the soul of injection molds and the key to ensuring excellent product quality.

-

Strong Professionalism in Operation, Combining Experience and Technology

There are many uncertainties in the early design and development of injection molds. Therefore, this process requires experienced practitioners to oversee. They mostly rely on the extensive knowledge and rich experience of mold designers to address issues closely related to design, such as jetting, warpage, weld lines, and gating.

-

Precise Temperature Control, Ensuring Production Stability

Controlling mold temperature involves heating the mold to the operating temperature. More importantly, maintaining a constant mold temperature at the operating temperature ensures the stability of the production process and the reliability of product quality.

These are some insights and experiences from Dongguan Yize Mold Processing Factory. When choosing a mold factory, we recommend first gaining a comprehensive understanding of the factory's scale, production capacity, past cases, and existing products. If conditions permit, it is best to visit the site for an inspection, which will reveal the true face of the injection molding factory from multiple dimensions. Dongguan Yize Mold Co., Ltd. is located at 62 Jinghai East Road, Shatou Community, Chang'an Town, Dongguan City. We sincerely invite friends from all walks of life to come for negotiations and cooperation to create a brilliant future together!

Home

Home