In the field of medical injection mold processing and customization, grasping the key elements is crucial to ensure a smooth customization process and products that meet high standards. Below are several indispensable elements to help you customize without worry.

I. In-depth Understanding of Product Characteristics

Firstly, it is necessary to comprehensively grasp the functional value points of the product and clarify the precautions in its design, such as tolerance control, appearance requirements, and anti-deformation measures. At the same time, it is essential to deeply explore the optimization space in product design, whether it is the optimization of the design structure or the adjustment of the product structure, striving for excellence to ensure the dual improvement of product performance and quality.

II. Skillfully Utilize the Observation and Learning Method

-

For unfamiliar mold structures, make full use of online resources to search for relevant materials and similar mold cases to broaden your horizons and enhance your understanding.

-

Actively draw on excellent mold structure cases and design techniques, analyze and compare them, learn from others' strengths, and make up for your own shortcomings.

-

In design practice, when encountering experienced masters, be humble and ask for advice, learn their working methods and thinking modes, and continuously improve your own design capabilities.

III. Summarize Experience and Continuously Improve

-

Insist on reviewing the mistakes you have made in the past every day, reminding yourself to avoid repeating them, and ensuring the steady improvement of work quality.

-

In the process of injection mold processing, maintain a keen insight, constantly think about whether there is room for improvement, avoid blind imitation, dare to innovate, and pursue excellence.

-

No matter what level your technical skills are at, always maintain the enthusiasm for learning and the determination to improve, constantly perfect yourself to adapt to the rapid changes in the industry.

IV. Strengthen Departmental Communication and Collaborate

-

At the beginning of injection mold processing and customization, raise targeted and critical questions to lay a solid foundation for subsequent work.

-

During the processing, be good at summarizing problems and take effective measures to improve them in a timely manner to ensure the smooth progress of the production process.

-

When communicating and coordinating with colleagues, adhere to the principle of being kind to others and create a good working atmosphere.

-

Face the problems that arise during the processing and customization process bravely, seek solutions in a timely manner, and communicate with various departments in a friendly and sincere attitude to jointly solve the problems and ensure the smooth progress of the project.

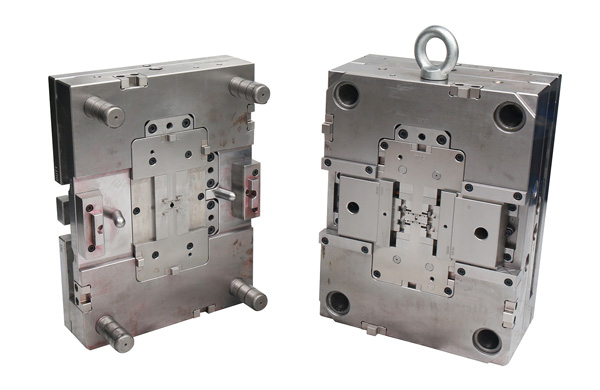

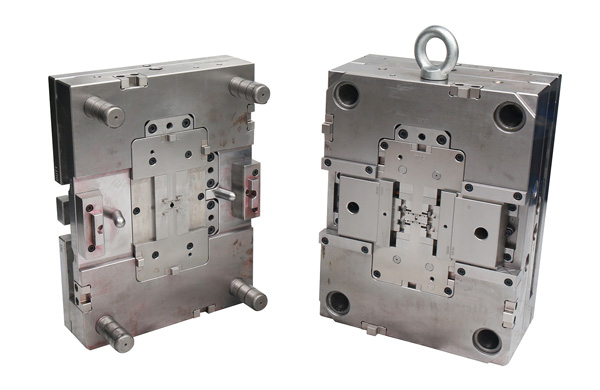

Dongguan Yize Mold Co., Ltd. - Your Professional Choice

Since its establishment in 2007, Dongguan Yize Mold Co., Ltd. has been deeply involved in the field of precision mold design and manufacturing, as well as precision injection molding product production. The company is headquartered in Dongguan, the manufacturing capital, with convenient transportation and logistics, enjoying a unique geographical advantage. We specialize in a complete set of solutions for the design, precision mold manufacturing, injection molding and assembly, and after-sales service of products such as automotive connectors, medical product injection molding, cleanroom injection molding, and PFA custom injection molding. For more information or to inquire about cooperation matters, please call 13302615729 (WeChat, WhatsApp same number), and we will serve you wholeheartedly!

Home

Home