In the field of medical mould manufacturing, the quotation process for mold opening is a crucial link, which not only concerns the customer's cost budget but also directly affects the profit margin of mold manufacturers. Below, we will elaborate on the complete process of medical mould opening quotation, as well as quotation strategies and estimation methods.

I. Detailed Process of Medical Mold Opening Quotation

-

Customer Needs Analysis

First, we need to thoroughly understand the customer's needs, including product specifications, usage environment, etc., to determine the selection of mold materials and heat treatment processes. This step is the basis of quotation and directly relates to the subsequent material costs and processing techniques.

-

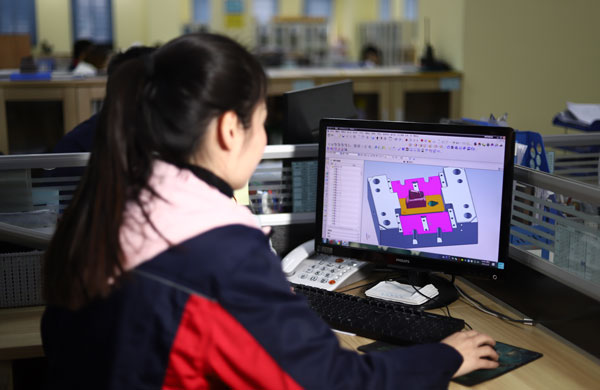

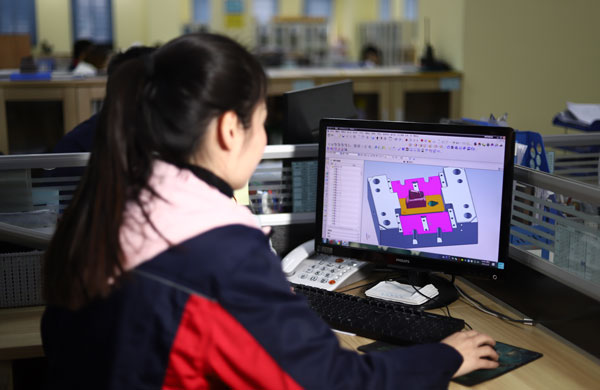

Material Selection and Preliminary Design Proposal

Based on customer needs, after selecting the appropriate mold materials, we will provide a rough mold design proposal. Through this proposal, we can calculate the blank weight of the mold (including mold core materials and mold base materials), and then derive the material cost, as well as the cost required for heat treatment.

-

Processing Cost Calculation

The calculation of processing costs is a key aspect of quotation. The processing cost of the mold core is usually proportional to its material cost, generally ranging from 1.5 to 3:1; while the processing cost of the mold base is relatively fixed, approximately 1:1. This ratio may be adjusted according to the complexity of the mold core.

-

Consideration of Risk Costs

To address possible unexpected situations, we will include 10% of the above total cost as risk costs in the quotation.

-

Inclusion of Design Costs

Design is the soul of mold manufacturing, so design costs are also an indispensable part of the quotation. We usually charge 10% of the total mold cost as design fees.

II. Quotation Strategy and Settlement Method for Medical Moulds

The settlement price of the mold is determined after the mold is manufactured and delivered for use. Ideally, the mold estimation, mold price, and mold settlement price should be equal. However, in practical operation, there may be fluctuations and errors among these three.

After the mold estimation is completed, we need to process it appropriately to form a formal quotation, which serves as the basis for signing the mold processing contract. Through repeated negotiations and discussions between both parties, a mold price acceptable to both parties is ultimately determined, and a formal contract is signed, thereby initiating the mold processing process.

III. Estimation and Quotation Techniques for Medical Moulds

After confirming the mold estimation, it cannot be directly used as the quotation. We also need to consider the overall market trend and communicate fully with the customer. Especially when the negotiated quotation is more than 10% lower than the estimation, we need to re-estimate the mold in detail to ensure that we sign the mold processing contract under the premise of breaking even and making a profit, and determine the final mold price.

Dongguan Yize Mould Co., Ltd. Profile:

Since its establishment in 2007, Dongguan Yize Mould Co., Ltd. has been deeply involved in the design and manufacture of precision molds and the production of precision injection molded products. The company is headquartered in Dongguan, the manufacturing capital, with convenient transportation and logistics, and a service network covering the globe. We specialize in the design, precision mold manufacturing, injection molding and assembly of products such as automotive connectors, medical product injection molding, cleanroom injection molding, PFA custom injection molding, as well as providing comprehensive after-sales service. For more information or to inquire about cooperation opportunities, please call +86 13302615729 (WeChat, WhatsApp same number), and we will serve you wholeheartedly!

Home

Home