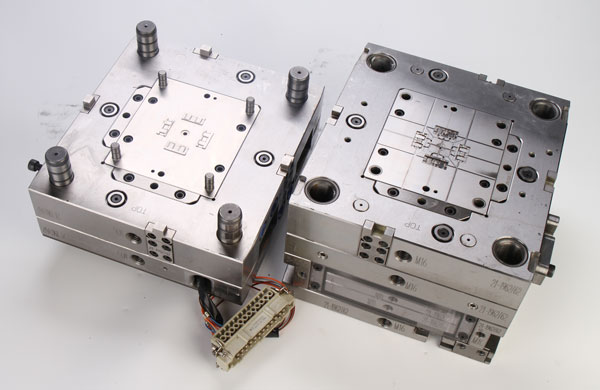

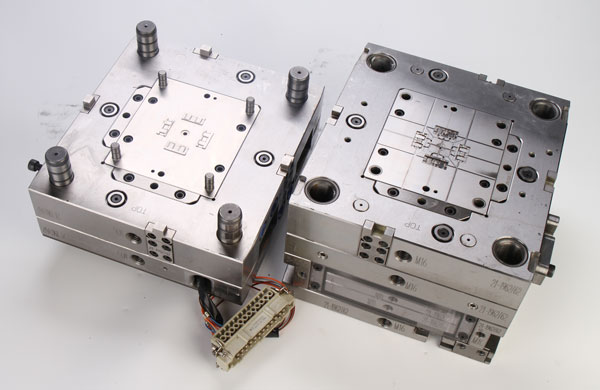

Recently, I stepped into the mold processing workshop, where rows of exquisite medical injection molds caught my eye. In the skilled hands of these mold craftsmen, cold steel is brought to life, transformed into precision models for producing plastic products. Today, let me take you on a deeper dive into those crucial little details in the processing of medical injection molds.

1. The Delicate Adjustment of Plastic Injection Speed

In the processing of medical injection molds, the regulation of injection speed is of utmost importance. It directly impacts the quality and appearance of the products. Specifically, the injection speed can be classically adjusted in four stages:

-

Stage One: For the straight and cross gate areas, we use medium to high speed to ensure the raw material fills the mold quickly, reducing injection time.

-

Stage Two: Near the injection gate, to suppress jetting marks, silver streaks, and other defects, we use low speed injection, allowing the raw material to flow into the mold more smoothly.

-

Stage Three: To prevent flow marks, weld lines, and other issues, we increase the injection speed again, ensuring the raw material fills the mold uniformly.

-

Stage Four: As the injection nears completion, to reduce gas burning, flash, and other defects, and to ensure a proper switch to the holding pressure position, we use medium or low speed injection.

2. The Magical Functions of the Plastic Injection Screw

The screw plays a pivotal role in the processing of medical injection molds. It is responsible not only for the conveyance and mixing of the raw material but also for venting, melting, and metering.

During the melting of the plastic raw material, seventy percent of the heat comes from the frictional heat generated by the screw's rotation, while the remaining thirty percent comes from the supplemental heat provided by the electric heaters. Furthermore, screws of different viscosities and sizes have different requirements for the melting speed. Low viscosity, small screws require faster melting speeds, while high viscosity, large screws require slower speeds. For composite materials, it is necessary to appropriately slow down the speed to ensure processing quality.

The little details in the processing of medical injection molds are countless, each one related to the final quality and performance of the product. Today, the editor from Yize Mold Injection Factory has shared this much with you. I hope this content is helpful to you. If you want to learn more about the details of plastic injection mold processing, welcome to visit the Yize Mold website: https://www.yizemould.com.

Home

Home