The mold opening cycle for medical injection molds is not a question that can be simply answered in one word. It is influenced by a combination of factors, including the product's design structure, size, requirements, cavity number, and performance. As a modern enterprise integrating plastic mold manufacturing and injection molding processing, Yize Mold, with years of experience in medical injection mold opening, understands how to accurately respond to customers' concerns about the mold opening cycle. Below, we will provide a detailed analysis of the key factors that determine the mold opening cycle for medical injection molds from several dimensions.

-

Product Structure: Complexity Determines Manufacturing Difficulty

Product structure, or the structural difficulty of the plastic part sample provided by the customer, is the primary factor in assessing the mold opening cycle. The more complex the shape of the plastic part, the more difficult it is to manufacture the mold, and the longer the processing time will be. The more parting surfaces, assembly positions, snap fits, holes, and ribs the mold structure has, the more difficult it is to guarantee its quality, the more problem points it will have, and the slower it will be to achieve the desired product effect.

-

Product Size: Larger Size, Longer Cycle

Product size is also a crucial factor affecting the mold opening cycle. The larger the size of the plastic mold, the longer the processing cycle will naturally be. At the same time, the processing time for related components will also increase.

-

Product Requirements: Varying Customer Needs Affect Cycle Times

Different customers have different requirements for products, which directly impact the manufacturing cycle of plastic molds. Whether the designed appearance is matte, glossy, or mirrored, it needs to be designed and processed according to specific requirements, thereby affecting the overall production schedule.

-

Product Material Performance: Special Requirements Increase Processing Difficulty

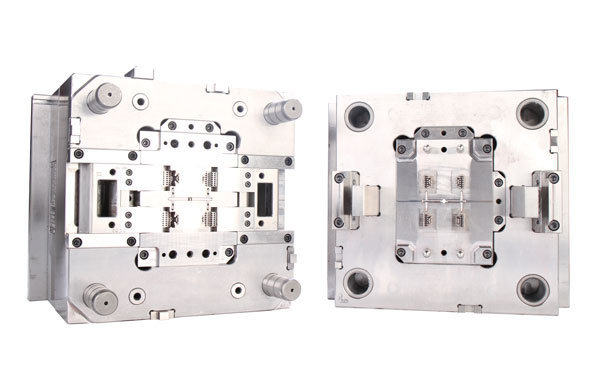

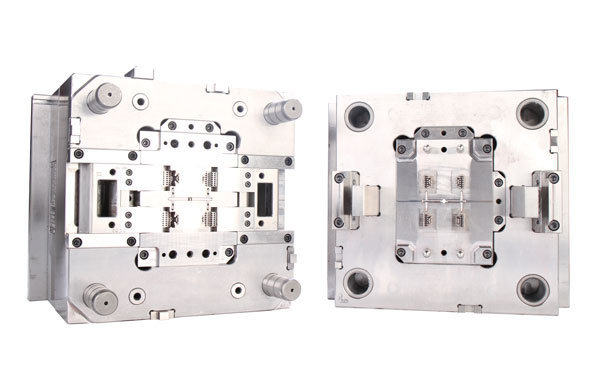

The material performance of the product also has different requirements for mold steel and processing techniques. For example, Yize Mold has previously processed molds for connectors and medical products, which sometimes require hardening and secondary CNC processing on precision grinding machines. These special requirements increase the processing difficulty and naturally extend the production cycle.

-

Mold Cavity Number: Market Demand Determines Cavity Number Changes

The number of cavities in the mold, or the number of products that can be produced from one set of molds, is also a factor affecting the mold opening cycle. When a new product's market has not yet fully opened up, the number of mold cavities may be relatively small to meet market demand. As the market matures, the number of mold cavities may be adjusted based on market demand.

In summary, the mold opening cycle for medical injection molds is influenced by a combination of factors. Generally, the mold manufacturing cycle is around 20-25 days, but the specific time depends on the specific mold. Suppliers usually provide conservative estimates, and if the product is urgently needed, the production time can be negotiated with the supplier. However, unforeseen circumstances may occasionally occur during production, so the actual cycle should be based on the actual situation. Once the medical injection mold is processed, the processing of plastic parts is relatively simple, and as long as the personnel and equipment are in place, the production cycle can basically be accurately estimated.

Home

Home