In recent years, with the vigorous development of the medical industry, the demand for precision medical injection molds has been increasing. Many well - known foreign mold manufacturing enterprises have set their sights on China, attempting to expand their markets by taking advantage of China's relatively low - cost labor and abundant resources. However, most of these foreign enterprises only place the production links in China, while keeping the core design and R & D technologies in their home countries. The design and R & D of precision medical injection molds can be regarded as the soul of mold production. Without these key links, only engaging in simple manufacturing work can yield extremely low economic benefits.

The entry of foreign mold enterprises is not a cause for celebration for China's domestic precision medical injection mold industry. They have not only deprived the domestic industry of its traditional price advantage but also intensified market competition, compressed the survival space of domestic enterprises, and carved up the product market that originally belonged to them.

Under such severe circumstances, if domestic precision medical injection mold manufacturers want to compete with foreign counterparts, they must strive for excellence in details, and the production process of precision medical injection molds is undoubtedly the top priority.

1. Early - stage Communication and Collaboration Are Crucial

In the stage of medical product development or new product trial - production, some users often focus all their energy on product research and development in the initial stage and ignore communication with precision medical injection mold manufacturing units. In fact, as soon as the product design plan is initially determined, it is necessary to get in touch with mold manufacturers as early as possible. This move has several significant advantages.

On the one hand, it can ensure that the designed product has good forming technology. Medical products have extremely high requirements for precision and quality. If the feasibility of mold production is not fully considered in the product design stage, modifications to the finalized design may be required later due to difficulties in part processing. This not only wastes a large amount of time and energy but may also affect the overall performance and quality of the product.

On the other hand, mold manufacturers can start design preparations in advance. Mold production is a complex and rigorous process that requires comprehensive consideration of numerous factors. Early involvement allows mold manufacturers to have more sufficient time for overall planning and detailed design, avoiding inadequate consideration due to time constraints and thus affecting the mold production schedule and quality.

In short, the production of high - quality precision medical injection molds cannot be achieved without close cooperation between the supply and demand sides. Only by working hand in hand can they effectively reduce costs, shorten the production cycle, and improve the market competitiveness of products.

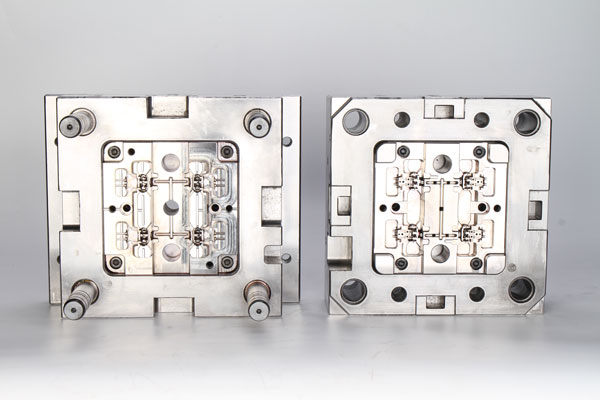

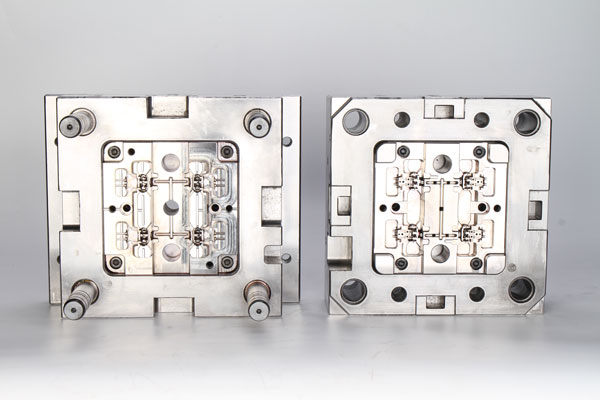

2. Precisely Select the Mold Type

There are a wide variety of molds. In the field of precision medical injection molds, it is also necessary to make precise selections according to different needs. Medical products have extremely strict requirements for the material, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, and economy of parts due to their special uses.

For example, for some medical devices that need to be in direct contact with the human body, such as syringes and infusion sets, the mold production must use materials that meet medical - grade standards to ensure the safety and non - toxicity of the products. At the same time, according to the specific shape and dimensional requirements of the product, an appropriate mold structure type should be selected, such as two - plate molds or three - plate molds, to ensure the forming quality and production efficiency of the product.

In addition, economy is also an important factor to consider when selecting mold types. On the premise of meeting product quality and production requirements, mold types with lower costs and shorter production cycles should be selected as much as possible to improve the economic benefits of enterprises.

3. Strictly Control the Quality of Mold Materials

The quality of mold materials is directly related to the service life of precision medical injection molds and the quality of products. The medical industry has extremely high requirements for the corrosion resistance, wear resistance, and high - temperature performance of mold materials.

When selecting mold materials, the production environment and use conditions of medical products should be fully considered. For example, for some medical products that need to be formed under high - temperature and high - pressure conditions, mold materials with good high - temperature performance and thermal stability, such as high - temperature alloy steels, should be selected to ensure that the molds do not deform or get damaged during long - term use.

At the same time, mold material suppliers should be strictly screened and evaluated, and suppliers with good reputation and quality assurance should be selected. When the materials arrive at the factory, strict inspection and testing should be carried out to ensure that the material quality meets relevant standards and requirements.

4. Pay Attention to the Processing Accuracy of Molds

The processing accuracy of precision medical injection molds is one of the key factors to ensure product quality. Medical products have extremely high requirements for dimensional accuracy, and any tiny error may affect the performance and use effect of the product.

During the mold processing, advanced processing equipment and processes, such as CNC machining centers and electrical discharge machining, should be used to improve the processing accuracy and surface quality of the molds. At the same time, the processing process should be strengthened in terms of monitoring and management, and operations should be carried out strictly in accordance with process requirements to ensure that each processing link meets quality standards.

In addition, the processed molds should be strictly inspected and debugged to promptly detect and solve existing problems and ensure that the molds can be put into normal use and produce medical products that meet quality requirements.

In conclusion, the production of precision medical injection molds is a complex and rigorous process. It is necessary to strictly control every link from early - stage communication and collaboration, mold type selection, material quality control, to processing accuracy, in order to produce high - quality precision medical injection molds and win a place for the development of China's domestic medical mold industry.

Home

Home