In the medical field, the strength of injection-molded products directly impacts the safety, reliability, and service life of medical devices. From precision components in surgical instruments to complex structures in implantable medical devices, enhancing product strength has become a core challenge in the industry. This article systematically explores key technical pathways for strength improvement from three dimensions: material science, mold design, and injection molding processes.

1. Material Selection: Balancing Strength and Biocompatibility

The strength enhancement of medical injection-molded materials must consider both mechanical properties and biological safety. Current mainstream solutions include:

-

Engineering Plastics Replacing General-Purpose Plastics: Materials like polycarbonate (PC) and polyether ether ketone (PEEK) are gradually replacing polyethylene (PE) and polypropylene (PP) due to their superior strength, stiffness, and heat resistance. For example, PEEK used in orthopedic implants exhibits a tensile strength exceeding 92 MPa and passes ISO 10993 biocompatibility certification, capable of withstanding complex stress environments in the human body.

-

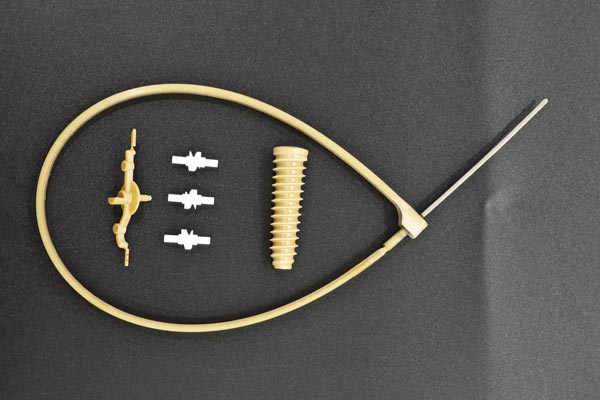

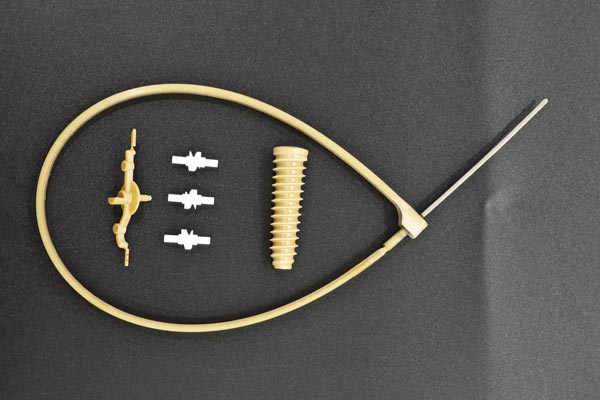

Fiber-Reinforced Composites: Adding glass or carbon fibers significantly boosts material strength. A 30% carbon fiber-reinforced PEEK composite achieves an 80% increase in tensile strength and 100% in flexural strength compared to pure PEEK while maintaining bioinertness. Such materials are widely applied in high-strength scenarios like artificial joints and spinal fusion cages.

-

Nanomodification Technology: Introducing nanofillers such as nano-silica or hydroxyapatite strengthens materials at the microscopic level. For instance, nanohydroxyapatite-modified polylactic acid (PLA) shows a 40% improvement in flexural modulus and matches bone tissue repair cycles in degradation rate, making it suitable for absorbable bone screws and plates.

2. Mold Design: Synergy of Structural Optimization and Precision Manufacturing

Molds are critical determinants of product strength, requiring optimization in the following areas:

-

Rib and Wall Thickness Design: CAE simulation analysis helps design triangular or trapezoidal ribs at key stress points, improving stiffness by over 30%. Adhering to the "uniform wall thickness" principle avoids stress concentration caused by abrupt thickness changes. For example, an insulin pen casing optimized for wall thickness reduced maximum deformation from 0.5 mm to 0.1 mm.

-

Fillet Transitions and Draft Angles: Sharp corners are replaced with R ≥ 0.5 mm fillets to mitigate stress concentration risks. Draft angle design balances strength and demolding efficiency. For deep-cavity medical catheter connectors, variable draft angles (1.8°–3° internally, 1.2°–2° externally) combined with TiN-coated ejector pins ensure uniform demolding force distribution.

-

High-Precision Mold Manufacturing: Five-axis machining centers (positioning accuracy ±0.001 mm) and electrical discharge machining (EDM) achieve mold cavity tolerances within ±0.003 mm. For micro-implant molds, critical dimensions can even reach ±0.001 mm, meeting high-precision strength requirements.

3. Injection Molding Process: Refinement of Parameter Control and Process Management

Injection molding parameters directly influence product internal structure and mechanical properties, necessitating precise control through:

-

Temperature Gradient Management:

-

Barrel Temperature: Crystalline plastics (e.g., PP) are controlled at 200–240°C, while amorphous plastics (e.g., PC) at 240–280°C to prevent degradation.

-

Mold Temperature: Dual-loop oil temperature controllers maintain uniformity within ±2°C, promoting homogeneous crystallization. For PEEK, a mold temperature of 180–200°C forms complete crystal structures, enhancing strength by 20%.

-

Cooling Time: Set based on product wall thickness (typically 2–3 times the holding pressure time) to ensure full solidification and minimize residual stress.

-

Pressure and Velocity Segmented Control:

-

Injection Pressure: Thin-walled products (e.g., cardiac stents) use 60–80 MPa low-pressure high-speed injection to avoid melt fracture; thick-walled products (e.g., orthopedic implant housings) employ 100–120 MPa high-pressure low-speed injection for complete filling.

-

Holding Pressure: Set at 70–80% of injection pressure for 8–15 seconds to compensate for material shrinkage and prevent sink marks.

-

Multi-Stage Injection Velocity: A "low-speed startup → high-speed filling → low-pressure holding" strategy reduces weld lines and flow marks. For example, a prefilled syringe piston achieved a 30% increase in weld line strength using three-stage injection (20 mm/s → 100 mm/s → 15 mm/s).

-

Screw Speed and Back Pressure Optimization: Screw speed is adjusted based on material properties (e.g., 30–60 r/min for polyoxymethylene (POM) to avoid shear-induced degradation). Back pressure (5–20 bar) improves melt uniformity and reduces unmelted particles.

4. Post-Processing and Inspection: The Final Safeguard for Strength

-

Annealing Treatment: Annealing PEEK at 70°C for 4 hours eliminates internal stress, reducing residual stress to below 3 MPa and preventing deformation after autoclaving.

-

Non-Destructive Testing: X-ray or ultrasonic scanning detects internal defects like shrinkage voids or bubbles. For example, X-ray inspection reduced shrinkage void rates in prefilled syringe pistons from 5% to 0.5%.

-

Mechanical Property Sampling: Five samples per batch undergo tensile, flexural, and impact tests to ensure strength deviations ≤ ±5%. For implantable devices, fatigue testing (e.g., 10⁷ cyclic loads) verifies long-term reliability.

5. Industry Case Studies: Practical Validation of Strength Enhancement

-

Case 1: Artificial Joint Implants

By combining carbon fiber-reinforced PEEK composites with conformal cooling mold technology, the product achieved a flexural strength of 320 MPa and a fatigue life exceeding 10⁷ cycles, meeting 15-year clinical requirements.

-

Case 2: High-Precision Pharmaceutical Packaging Shells

Using glass fiber-reinforced PA material and multi-stage injection molding, the product maintained wall thickness tolerances within ±0.02 mm and passed 1.5 m drop tests without cracking.

Conclusion

Enhancing the strength of medical injection-molded products is a systematic endeavor requiring holistic optimization across material selection, mold design, process control, and post-processing inspection. With the integration of emerging technologies like 3D-printed molds and IoT-enabled smart monitoring, future medical injection molding will advance toward higher precision, strength, and cost-efficiency, driving the localization and upgrading of high-end medical devices.

Home

Home