Medical injection molding is a core process in modern medical device manufacturing, with products directly impacting patient safety and health. However, due to the complexity of the process, production often faces interference from uncontrollable factors such as material performance fluctuations, environmental changes, and equipment instability. These issues can lead to product defects, reduced efficiency, or even compliance risks. This article systematically analyzes key uncontrollable factors in medical injection molding and proposes targeted strategies to provide industry references.

1. Main Uncontrollable Factors in Medical Injection Molding

-

Raw Material Performance Fluctuations

Medical-grade materials (e.g., PP, PE, PVC, silicone) may vary in molecular weight distribution, melt flow rate, or additive content due to supplier batch differences or storage conditions. For example, moisture absorption can cause bubbles or silver streaks, while poor thermal stability may lead to degradation or discoloration, affecting biocompatibility and mechanical properties.

-

Environmental Condition Variations

Temperature, humidity, and cleanliness significantly impact injection molding. High humidity can cause material absorption, leading to flash or surface defects, while temperature fluctuations may affect mold cooling efficiency, resulting in inconsistent shrinkage or warping. Insufficient cleanliness can introduce particulate contamination, threatening the safety of sterile medical devices.

-

Equipment Stability Issues

Critical components like hydraulic systems, temperature control modules, and screw speeds directly influence product quality. For instance, temperature control failures may cause melt temperature deviations, leading to degradation or incomplete filling, while screw wear can result in uneven plasticization and internal stress.

-

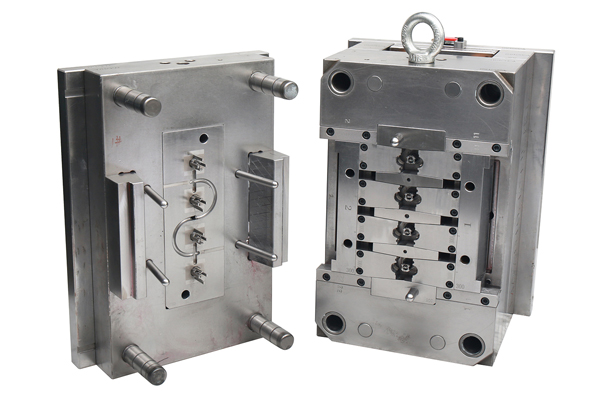

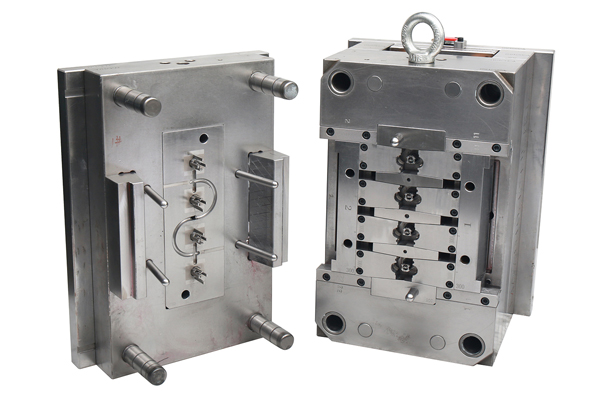

Mold Wear and Aging

Molds are subject to high-pressure and high-temperature conditions, leading to cavity wear, ejector pin sticking, or cooling channel blockages. These issues can cause flash, burrs, or uneven cooling, affecting product dimensions and surface quality.

-

Human Operational Errors

Despite high automation, manual involvement in mold installation, parameter settings, and quality inspection remains necessary. Skill gaps, fatigue, or negligence can lead to parameter input errors or mold misalignment, resulting in batch defects.

2. Countermeasures for Uncontrollable Factors

-

Strengthen Raw Material Quality Control and Preprocessing

-

Implement strict supplier audits and select certified medical-grade material suppliers.

-

Conduct batch testing for key indicators (e.g., melt flow rate, moisture content) and perform pre-drying (e.g., 80°C for 2–4 hours for PP) to eliminate moisture.

-

Develop alternative material formulations to improve process robustness.

-

Create a Controllable Production Environment

-

Maintain a temperature-controlled (20–25°C) and humidity-controlled (40–60%) cleanroom.

-

Use HEPA filters and laminar flow hoods to reduce particulate contamination.

-

Install real-time monitoring systems for temperature, humidity, and particle counts, with automatic alerts for deviations.

-

Equipment Maintenance and Smart Upgrades

-

Establish preventive maintenance schedules for injection molding machines and molds.

-

Integrate IoT sensors for real-time data collection and AI-driven anomaly detection.

-

Adopt redundant designs for critical components (e.g., dual temperature control modules) to ensure continuity.

-

Full Lifecycle Mold Management

-

Optimize mold design using CAE simulation for balanced flow and efficient cooling.

-

Use high-hardness steels (e.g., H13, S136) to extend mold life.

-

Implement quick mold change systems to reduce downtime.

-

Standardized Operations and Personnel Training

-

Develop SOPs for process parameters, mold installation, and quality inspection.

-

Require certification for operators (e.g., ISO 13485, GMP compliance) and conduct regular refresher training.

-

Introduce error-proofing mechanisms (e.g., parameter locks, automated visual inspection) to minimize human errors.

3. Case Study: Resolving Surface Defects in Medical Catheters

A manufacturer encountered silver streaks on disposable infusion catheters due to raw material moisture absorption. Solutions included:

-

Installing dehumidifiers in the warehouse to maintain humidity below 30%.

-

Adding a 4-hour drying process for PP granules using a hot-air circulation oven.

-

Integrating humidity sensors in the hopper to trigger automatic shutdowns if thresholds were exceeded.

Post-implementation, defect rates dropped from 5% to 0.2%, saving over $2 million annually in rework costs.

4. Conclusion

While uncontrollable factors in medical injection molding cannot be entirely eliminated, systematic quality control, environmental management, equipment maintenance, and personnel training can significantly mitigate their impact. Future advancements in digitalization (e.g., digital twins, big data analytics) will drive the industry toward zero-defect, high-flexibility, and intelligent manufacturing, ensuring reliable global healthcare solutions.

Home

Home