A set of standard mold production and processing process is very important for mold manufacturing enterprises, the production and processing of the mold plays a guiding role, but also the guarantee of product quality. So what are the steps of custom mold production and processing process? The following follow Yize Mould editor to take a look.

1. Mold blank preparation. Mold blanks are mostly metal. Operators are mainly based on the specific shape and geometry of the blank for selection. For thin plate blanks, you can use ordinary blanking drop or precision blanking down. If you need to forge ring-shaped parts, you can also use the pipe cutting blanks.

2. Rough machining of parts. Rough machining of parts we take milling as an example, as long as the outer contour of the part is given to generate the machining trajectory. And you can automatically increase the arc at the sharp corners of the trajectory to ensure that the trajectory is smooth, in order to meet the requirements of high-speed machining. It is mainly used for milling planes and milling slots. Multiple contours can be selected for machining.

3. semi-finishing machining. The semi-finishing stage is to complete the processing of secondary surfaces and prepare for the finishing of primary surfaces.

4. heat treatment. Heat treatment is to put the material in a certain medium heating, insulation, cooling, by changing the material surface or internal organization, to control its performance of a comprehensive process. Heat treatment process generally includes heating, holding, cooling three processes, sometimes only heating and cooling two processes. These processes are connected to each other, can not be interrupted.

5. Finishing . Finishing is smaller than the roughing of the machining allowance, the choice of good props for cutting, control the speed of props and rotational speed, pay attention to the size of the material and the appearance of gloss.

6. Cavity surface treatment. Mold different surface treatment methods, can change the mold surface chemical composition, organization, performance, significantly improve and enhance the surface performance of the mold. For example, hardness, abrasion resistance, friction properties, mold release properties, thermal insulation, high temperature and corrosion resistance and other properties. This step is to improve the quality of the mold.

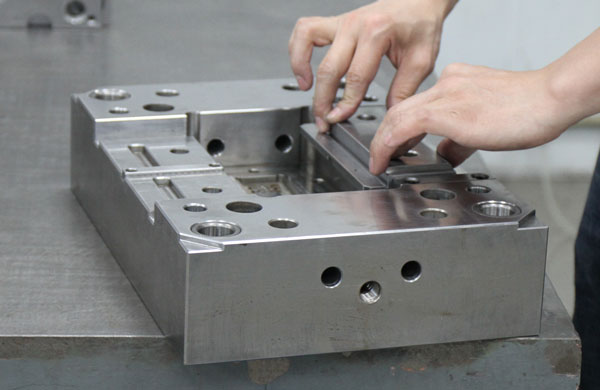

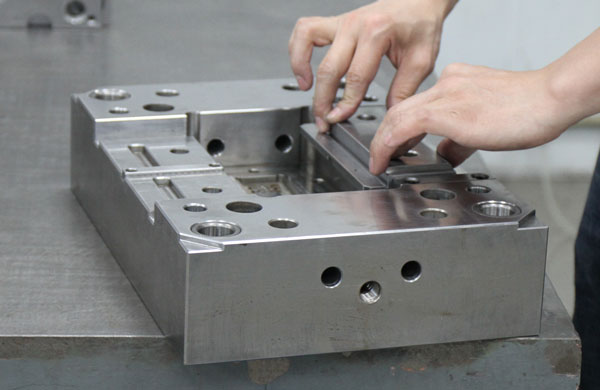

7. Mold assembly. According to certain specified technical requirements, the combination of parts into components, and combined into components to the whole machine process. There are two forms of assembly, a fixed assembly, a mobile assembly. Different batches of production to choose different assembly methods.

In the assembly process, some mold parts need to be polished and trimmed. Mold assembly is the main content of the mold has been processed mold parts and standard parts according to the mold assembly diagram requirements for assembly into a complete mold. After the mold test also need to adjust and repair some parts, so that the mold production parts in line with the requirements of the drawing, and the mold can work normally and continuously, the mold processing is complete.

Yize Mould is committed to providing customers with systematic intelligent manufacturing solutions for products in related fields. The factory is equipped with many imported all-electric injection molding machines and several fully automated assembly lines, which have won the unanimous approval of many enterprises.

Home

Home