Medical injection molding plays a pivotal role in the modern medical injection industry, widely used in the production process of medical plastic products. From laryngeal speculum tips to syringe casings, from medical devices to precision components, its application range is extensive and diverse. However, for many medical device vendors, a crucial question remains: how much does it cost to make an injection mold?

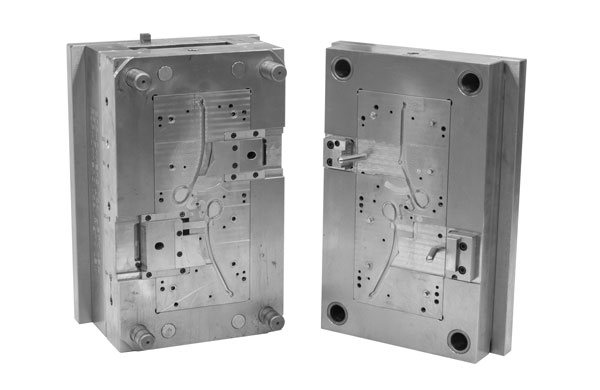

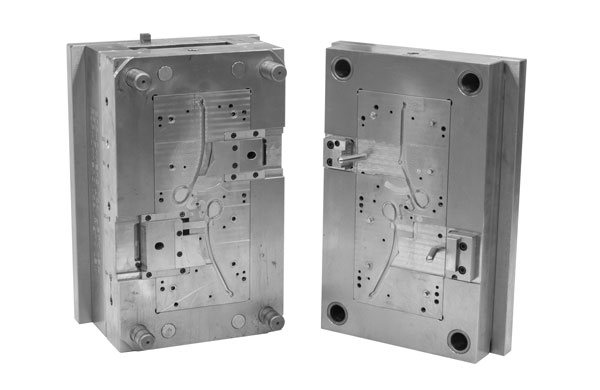

The price of medical injection molds varies due to multiple factors, with mold size, complexity, and material selection being the most significant. Generally, larger and more complex molds require more material and processing time, resulting in higher prices. Additionally, the choice of materials also impacts the price, as medical molds made from nickel-based alloy materials are typically more expensive.

Apart from the mold itself, the production capacity and technical level of the mold manufacturer also influence the price. Some manufacturers with advanced equipment and technology may charge higher prices, but they usually provide higher-quality products and shorter delivery times, which are highly attractive to medical device companies.

However, price is not the only factor that medical device companies should consider when selecting a medical injection mold manufacturer. Quality and reliability are equally important. A low-quality mold may lead to failures and delays in the production process, thereby increasing costs. Therefore, choosing a manufacturer with a good reputation and rich experience is particularly crucial.

Furthermore, companies should also consider the design and innovation capabilities of the mold. A mold with innovative design may bring significant advantages in production efficiency, product quality, and cost savings. Therefore, when selecting a medical mold manufacturer, it is essential to consider not only the price but also their design capabilities and innovative spirit.

In summary, the price of making a medical injection mold varies due to multiple factors, including size, complexity, material selection, and the production capacity and technical level of the mold manufacturer. For medical companies, selecting a medical injection mold manufacturer with reasonable prices, reliable quality, and innovative design capabilities is crucial. By comprehensively considering these factors, companies can make informed decisions and choose the most suitable medical injection mold for their production process, thereby achieving the perfect balance of cost, quality, and innovation.

Yize Mould has been dedicated to the development and manufacturing of precision medical injection molds since 2006, providing full-process processing services. We possess comprehensive and systematic mold development capabilities, from mold design, manufacturing, assembly to inspection, and are equipped with an ISO Class 7 cleanroom, providing robust support for the development and production of high-precision medical molds and medical device injection molding. Choose Yize Mould to make your medical injection molding production more efficient, reliable, and innovative.

Home

Home