In-depth Analysis of the Design and Precision Mold Manufacturing Process for Injection-Molded Medical Products

DATE:2024-11-04 HITS:1097

I. Innovative Design Strategies for Injection-Molded Medical Products

When designing injection-molded medical products, our focus is always on meeting the market demands of specific applications, while striving to reduce overall costs and enhance product performance. Designers must carefully plan each step from multiple dimensions:

Thorough Market Research and User Insights

Market research is a crucial initial step in design. Through detailed market surveys, we can directly capture users' true needs and feedback for medical products, providing rich and specific references for design.

Precise Specification and Drawing Design

Specification design involves considerations of functionality, appearance, and other dimensions to ensure the perfect fit of product form and size. Through meticulous mold release design, tolerance control, and the precise drawing of 2D and 3D diagrams, we lay a solid foundation for subsequent manufacturing processes.

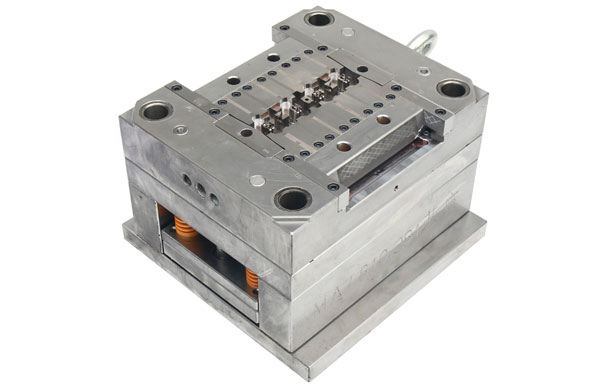

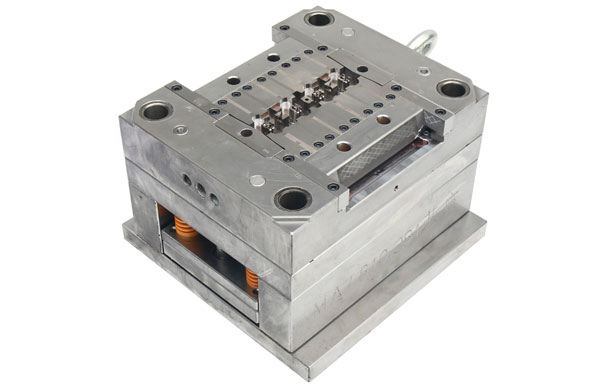

The Science and Art of Mold Design

Mold design is the soul of injection-molded medical product manufacturing. It not only requires meeting the high precision requirements of products but also finding the optimal balance between cost control and production efficiency, ensuring product quality while reducing waste during production.

Rigorous Material Selection

Material selection is directly related to the safety and reliability of medical products. We strictly select non-toxic, harmless injection molding materials to ensure product safety and stability during use.

II. Precision Mold Manufacturing Process for Injection-Molded Medical Products

Molds, as the cornerstone of injection-molded medical product manufacturing, undergo multiple meticulous processes including design, manufacturing, and debugging:

The Wisdom and Craftsmanship in Mold Design

During the mold design phase, we comprehensively consider core parameters such as mold structure, precision, and size, combining material characteristics and service life requirements to carefully plan the optimal design solution.

The Exquisite Craftsmanship in Mold Manufacturing

Mold manufacturing is a combination of technology and art. We utilize advanced precision equipment, coupled with the skilled craftsmanship of technicians, to complete the manufacturing and assembly of mold parts, ensuring every detail meets the highest standards.

The Rigor and Attention to Detail in Mold Debugging

Mold debugging is the final line of defense in ensuring product quality. Through precise analysis of debugging data, we seamlessly align actual production parameters with mold design. Simultaneously, we conduct comprehensive inspections of the mold's materials, structure, and operational guidelines, ensuring smooth injection molding production and promptly addressing any issues that may arise during the process.

Home

Home