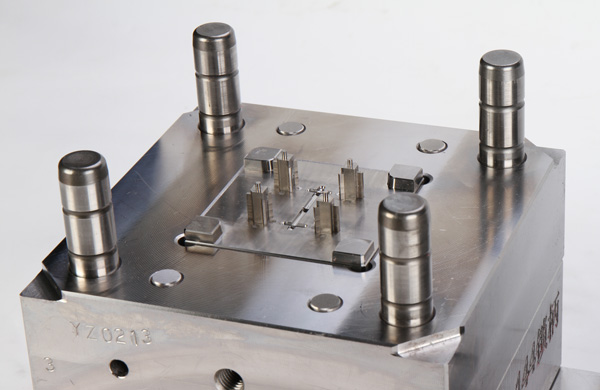

Essence and Key Points for medical injection mould Design

Precision and meticulousness are crucial for success in the design process of medical injection moulds. The following points require special attention:

Gate Design: Should be cleverly placed in areas with thicker product walls to ensure a smooth injection process and complete filling. At the same time, the location should be concealed, not affecting the product's appearance and function, with edges or bottoms being preferred choices.

Cold Slug Management: Design cold slug wells near the gate and equip them with pullers to facilitate smooth mold release of the runner.

Multi-Point Gating Strategy: For large or flat products, adopting multi-point gating can effectively prevent warping and short shots.

Flow Path Optimization: The gate position should minimize the plastic's flow path in the mold, reducing pressure loss and facilitating mold venting.

Core Protection: Avoid placing gates next to slender cores to prevent direct impact from the plastic flow, which could cause deformation.

Gate Size Customization: Based on product characteristics (size, shape, structure, and plastic type), initially set a small gate size and adjust according to mold trial results.

Weld Line Management: Predict weld line positions through mold flow analysis, assess their impact on the product, and improve if necessary by adding cold slug wells.

Symmetric Gating Principle: For multi-cavity molds with the same product, adopt symmetric gating; when different products share a mold, prioritize placing the larger product near the main runner.

-

Wise Choices for Medical Injection Molding Processing

Equal Emphasis on Design and Manufacturing

In the early stages of product development, do not neglect communication with mold manufacturers. Early collaboration can ensure:

Designed products have good formability, avoiding later modifications.

Mold manufacturers have sufficient time to prepare, ensuring thorough design consideration and avoiding delays.

Close cooperation between both parties effectively controls costs and shortens cycles.

-

Comprehensive Consideration Beyond Price

When selecting mold suppliers, various factors such as quality, cycle time, and service must be considered:

Molds are diverse, and the appropriate type must be selected based on specific needs.

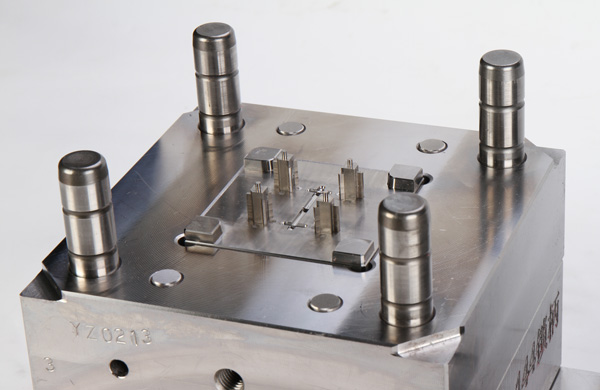

High-precision molds require strict processing techniques and materials, as well as advanced CAD/CAE/CAM technology.

Special molding needs may involve advanced technologies such as hot runners and gas-assisted molding.

Assess suppliers' equipment capabilities (e.g., CNC, EDM, wire cutting) and software support.

Large molds may also require additional machine functions, such as blank holders, feeding devices, and mold protection mechanisms.

Selection should comprehensively evaluate processing capabilities, management levels, and technical experience, avoiding price traps.

-

Integrated Collaboration for Quality Assurance

A high-quality mold is not the sole requirement for producing qualified products; matching processing equipment and skills are also necessary.

Ideally, mold manufacturing and product processing should be handled by the same team to reduce communication costs and ensure consistent quality.

If integration is not feasible, responsibilities should be clearly defined, and contract terms detailed to protect both parties' interests.

In summary, the design and processing of medical injection moulds is a systematic and meticulous process requiring close collaboration between designers and manufacturers, as well as strict control over every detail, to achieve high-quality medical products.

Keywords: medical injection mould, Design Points, Processing Points, Integrated Collaboration, Quality Control

Summary:

The article outlines key elements in designing medical injection moulds, including gate placement and cold slug management, and emphasizes the importance of integrated design and manufacturing, comprehensive supplier evaluation, and collaborative quality assurance in the processing stage to ensure mold quality and production efficiency.

Home

Home