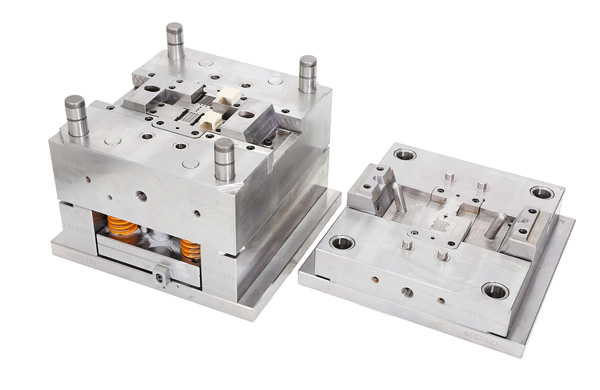

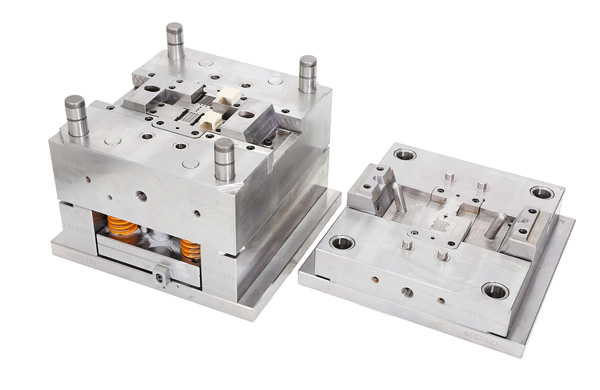

In the production of medical plastic products, injection molds serve as the core tool, and their quality directly impacts the final product's quality. However, surface gloss defects in molds are often a challenging issue during the processing. Injection molds, precisely composed of moving and fixed parts, inject plastic raw materials into the mold cavity through an injection molding machine. After cooling and solidification, the desired medical injection-molded components are obtained. So, how should we tackle the problem of poor mold surface gloss?

Below are the major causes and corresponding solutions for addressing surface gloss defects in plastic injection molding, summarized by Shibang Plastics based on years of experience. We hope they can provide valuable support for your production.

-

Mold Condition Optimization:

-

The mold's finish is a primary factor. Ensure the cavity surface is free of rust and defects, and that the mold's ventilation system is unobstructed.

-

Improvement of Gating System Design:

-

Optimize the gating system, including increasing the cold slug well, widening the runner, and polishing the main runner, branch runners, and gate to reduce resistance and heat loss during plastic flow.

-

Temperature Control Adjustment:

-

Raise the material and mold temperatures to an appropriate range. If necessary, use local heating techniques at the gate to promote uniform filling and solidification of the plastic.

-

Injection Parameter Optimization:

-

Increase processing pressure, injection speed, and injection time, and ensure sufficient back pressure to enhance the plastic's density and surface gloss.

-

Plastic Plasticization and Cooling Management:

-

Ensure the plastic is fully plasticized while avoiding degradation caused by overheating. For thick-walled parts, pay special attention to uniform heating and sufficient cooling.

-

Cold Material Management:

-

Prevent cold material from mixing into the product. Consider using self-locking springs or appropriately lowering the nozzle temperature to reduce the impact of cold material on the product's surface gloss.

-

Raw Material and Additive Quality Control:

-

Choose high-quality plastic raw materials and colorants, avoiding materials containing moisture or other impurities. Also, select high-quality lubricants to ensure the plastic's flowability and surface quality.

-

Ensuring Clamping Force:

-

Ensure sufficient clamping force to avoid issues such as flash and burrs caused by incomplete mold closure, which can affect the product's surface gloss.

In summary, manufacturing high-quality medical molds requires comprehensive consideration of various aspects, from mold design to processing parameters, and raw material selection. Dongguan Yize Mold, as a leader in precision mold design and manufacturing, is committed to providing customers with a comprehensive solution that includes mold design, precision manufacturing, injection molding, assembly, and after-sales service, helping customers create excellent medical plastic products.

Home

Home