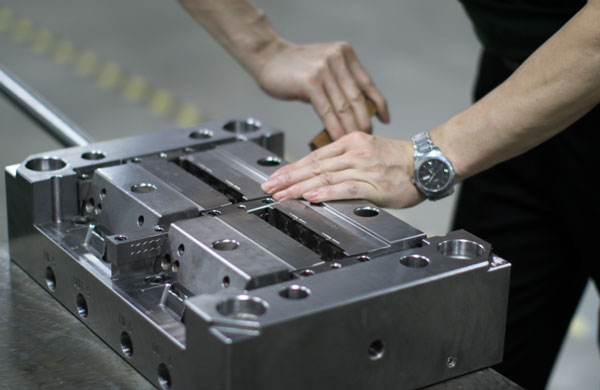

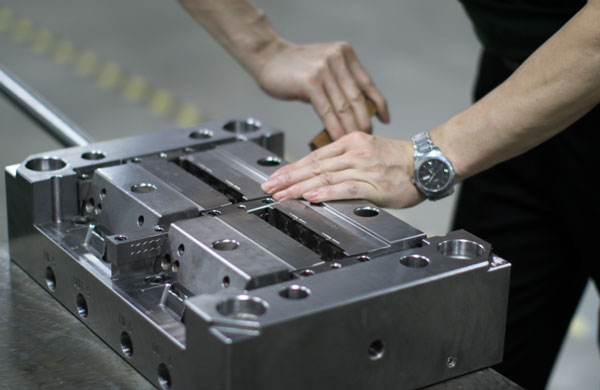

In our daily lives, the text and patterns on plastic products add a touch of vividness and interest. Manufacturers employ various methods, such as silk screening, hot stamping, pad printing, and more, to impart these texts onto products. Today, I will reveal another unique process – engraving on molds and then transferring the text onto the products. So, how do injection molding factories achieve engraving on molds? Let's delve into it together.

1. Laser Engraving: A Precise and Efficient Choice

Injection molding factories often use laser engraving technology for molds, which can mark complex graphics, texts, barcodes, and more on various materials. This technology not only engraves quickly but also offers permanence, making it an ideal choice for enhancing product quality. Sometimes, manufacturers also use this method to engrave mold numbers, manufacturer names, and other important information on the molds.

-

High Precision and Aesthetic Appeal: Laser engraving offers extremely high precision and a beautiful finish, meeting the high aesthetic requirements of products.

-

Quality Assurance: The technology is highly stable and safe, ensuring reliable marking processes.

-

Permanent and Tamper-Proof: The text or patterns engraved by laser will never fall off, are heat-resistant, and have strong anti-counterfeiting properties.

-

Low Power Consumption: The total power consumption is only 1.5KW, with minimal electricity usage per hour, making it energy-efficient and environmentally friendly.

-

Low Maintenance Cost: The semiconductor light-emitting module has a long service life, meeting the needs for long-term and stable operation, and reducing maintenance costs.

2. Mold Sunbathing (Photochemical Etching): The Wisdom of Traditional Craftsmanship

In addition to laser engraving, mold sunbathing is another traditional process for marking and engraving on molds. When performing sunbathing, special attention must be paid to the depth of etching. If the depth is too deep, the text may connect; if it's too shallow, it may not be clearly visible on the plastic parts. Generally, it is recommended to control the etching depth at around 0.1mm, but the specific depth should be determined based on actual conditions. The purpose of sunbathing is to ensure that the text is clearly visible on the plastic products, thereby enhancing the overall aesthetic appeal and quality of the products.

Here, it is worth mentioning a company with rich experience in precision mold design and manufacturing, as well as precision injection molding production – Dongguan Yize Mold Co., Ltd. Since its establishment in 2007, the company has been committed to providing customers with a complete set of solutions for the design, precision mold manufacturing, injection molding and assembly, and after-sales service of products such as automotive connectors, medical product injection molding, cleanroom injection molding, and PFA custom injection molding. Headquartered in Dongguan, the manufacturing capital, with convenient transportation and logistics, the company welcomes customers to inquire (Contact number: 13302615729, WeChat, WhatsApp same number).

In summary, both laser engraving and mold sunbathing are important processes for engraving on molds in injection molding factories. These processes not only enhance the aesthetic appeal and quality of products but also provide strong support for product anti-counterfeiting and traceability.

Home

Home