For friends who have experience in e-commerce, they surely know that "price" is always the frequently asked keyword when customers inquire online. Different industries have different focuses for these inquiries. Take my industry, medical injection mold processing, as an example. Customers often ask questions like, "How much does it cost to process a medical injection mold?" or "How much would it cost to make this equipment shell?" and so on. I usually can't give a flat rate for these custom-made products because they involve a wide range of design components, and each product has a different structure and production process. Therefore, we can't determine the price at a glance. So, how can we find out the exact cost of this injection-molded part? Let me reveal it to you next.

Before giving a formal quote for medical injection mold processing parts, we need to obtain the customer's 3D drawings or sample physical objects. After our engineers communicate with the customer to confirm the details such as structure, material, process, etc., we can then proceed with the quotation. The quotation includes the costs of both the product and mold manufacturing, which are usually calculated based on the following aspects.

1. Material Cost Calculation

The material cost is calculated by multiplying the material price by the product weight. For colored parts, we simply use the raw material price. For black parts, the calculation is based on the specific recycled material or product requirements. The processing fee is related to the number of mold cavities, molding cycle, and product weight. The machine cost is calculated based on tonnage, down to the cost per second. However, if there are many mold cavities, the weight is heavy, and the molding cycle is short, the processing fee will be lower, and so will the unit price.

2. Product Unit Price Calculation

The product unit price consists of both the material cost and the processing fee. The specific calculation formula is: Product Unit Price = (Actual Weight + Waste) * Material Unit Price + Molding Cycle * Unit Price (per second) / Number of Cavities. If the customer has specific packaging requirements, the packaging cost will also be added.

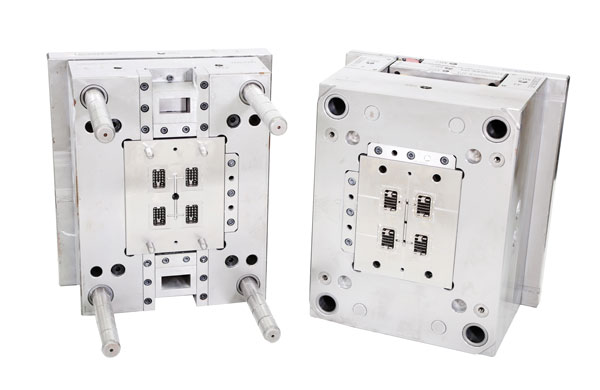

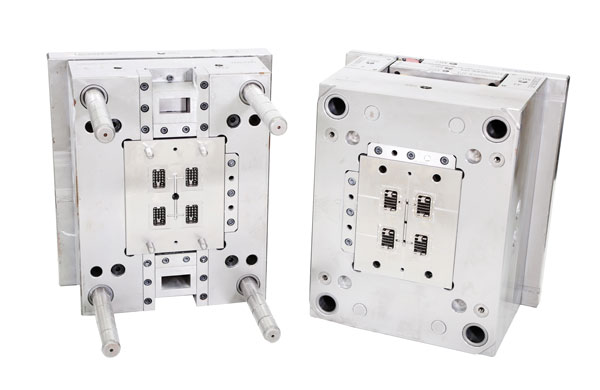

3. Mold Price Evaluation

The evaluation of the mold price first requires selecting the steel material, and then assessing based on the product's size and structure. For example, whether polishing or texture finishing is needed, which involves many processes. Moreover, the mold processing cycle is relatively long, and the specific price needs to be determined based on the product.

In summary, through the above calculations, we can obtain the cost of medical injection mold processing. Of course, the specific cost varies depending on the product. If you want to learn more information, feel free to send us your drawings for a free quote. We also have engineers available online to provide one-on-one mold technical support, optimize product structures, and propose the best production and processing solutions. Shibang Injection Plastic Mold Factory has 23 years of experience in mold injection processing. We specialize in providing medical plastic injection mold products, household appliance shells, cosmetic packaging, and other types of injection-molded products. We have rich processing and manufacturing experience. We look forward to working with you to create a brilliant future!

Home

Home