In the production process of medical injection molded parts, mold temperature is undoubtedly a crucial factor that determines quality. The precise control of mold temperature, whether hot or cold, is essential. A hot mold surface can maintain the liquid state of the semi-finished product for an extended period, ensuring sufficient pressure is formed within the cavity. The mold temperature controller can stabilize the temperature of the thermal fluid within a narrow range of 1°C to 3°C, with the specific temperature set according to the quality requirements of the medical injection molded parts. So, how do medical injection molding manufacturers control mold temperature? Today, let's have Yize Mold's editor reveal the secrets.

Firstly, it must be recognized that if plastic enters the cavity under low pressure in a suspended state, even for a short period, slight contact with metal can cause stains, commonly referred to as gate stains.

The core purpose of controlling mold temperature and its impact on injection molded parts cannot be ignored. In the injection molding process, the primary goal of controlling mold temperature is to heat the mold to the appropriate working temperature and maintain this temperature constant. This optimizes cycle time and ensures the stable and excellent quality of injection molded parts. Mold temperature directly affects surface quality, flowability, shrinkage rate, injection cycle, and deformation, among other aspects.

Excessive or insufficient mold temperature has different effects on different materials. For thermoplastics, a slightly higher mold temperature usually improves surface quality and flowability but prolongs cooling time and the injection cycle. Conversely, a lower mold temperature reduces shrinkage within the mold but increases the shrinkage rate of the injection molded part after ejection. For thermosetting plastics, a higher mold temperature shortens the cycle time, which is primarily determined by the time required for the part to cool. Additionally, in plastic processing, a higher mold temperature reduces plasticization time and lowers the number of cycles.

It's worth noting that for each type of plastic and plastic part, there is a limit to the mold surface temperature. Once this limit is exceeded, one or more adverse effects may occur, such as component flash. The higher the mold temperature, the lower the flow resistance. In many injection molding machines, this means that the flow rate through the gate, runner, and cavity is faster. Since the injection flow control valve cannot correct this change, a faster filling speed results in higher effective pressure in the gate and cavity. Generally, an increase in mold temperature reduces the solidified layer of plastic in the mold cavity, making it easier for the molten material to flow within the mold cavity, thereby obtaining larger part weights and better surface quality. Simultaneously, an increase in mold temperature enhances the tensile strength of the parts.

Many molds, especially those for engineering thermoplastics, operate at relatively high temperatures. If the mold lacks good insulation, heat loss to the air and injection molding machine can be comparable to heat loss in the injection cylinder. Therefore, the mold should be insulated from the machine plate. If possible, the mold surface should also be insulated. For hot runner molds, heat exchange between the hot runner components and the cooled injection molded parts should be minimized.

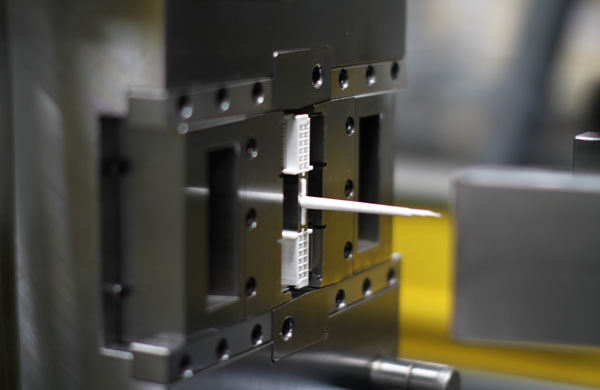

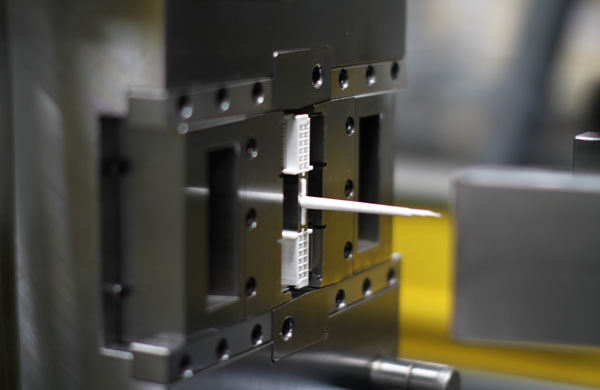

That's all for today's sharing on how medical injection molding manufacturers control mold temperature. If you want to learn more about precision injection molding processing, please continue to follow Dongguan Yize Mold Co., Ltd. Established in 2007, Dongguan Yize Mold Co., Ltd. is located in Dongguan, the manufacturing capital, with convenient transportation and logistics. The company has been engaged in precision mold design and manufacturing, as well as precision injection molding production for many years. It specializes in a complete set of solutions for the design, precision mold manufacturing, injection molding and assembly, and after-sales service of automotive connectors, medical product injection molding, cleanroom injection molding, PFA custom injection molding, and other products. Welcome to call for consultation: +86 13302615729 (WeChat, WhatsApp same number).

Home

Home