With the constant changes in the market and the increasing diversification of public demands, the plastic injection mold manufacturing industry is booming at an unprecedented rate. The rapid development of this industry not only affects the price, structure, and delivery time of injection molds, but also presents more considerations for users when choosing injection mold manufacturers. Today, the editor of Yize Mold will take you to explore the future development trends of medical injection mold manufacturing.

1. Price Trend: Technological Innovation Drives Cost Optimization

With the continuous improvement and innovation of plastic molding processes, gas-assisted molds and molds adapted to low-pressure injection molding and other advanced processes are gradually emerging. Medical plastic parts have extremely high requirements for precision, including dimensional accuracy, geometric accuracy, and surface accuracy (such as gloss, color, etc.). In order to meet these stringent standards, the industry will continue to delve into low-pressure injection molding processes and molds, as well as injection compression molding processes and molds. Gas-assisted molding technology has become increasingly mature, which not only improves the external quality and surface finish of plastic parts but also has the advantages of low injection pressure, small finished product deformation, and ease of molding products with large wall thickness differences. At the same time, it can effectively save materials and improve production efficiency, thereby significantly reducing costs.

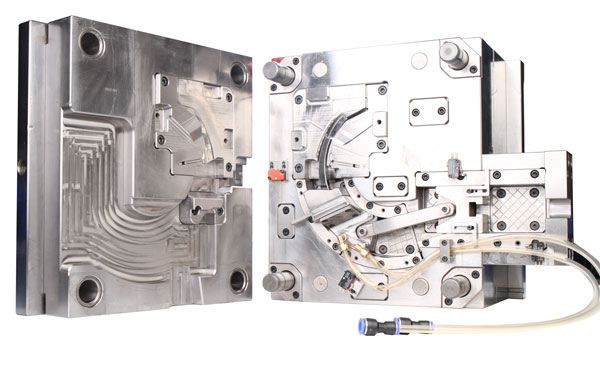

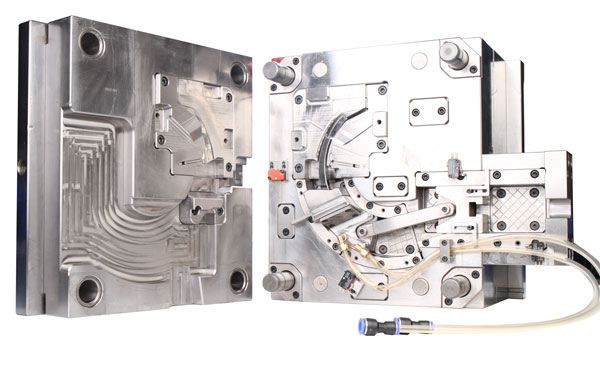

2. Structural Trend: High Precision and Complexification Go Hand in Hand

With the in-depth practice of the concepts of "replacing steel with plastic" and "replacing wood with plastic," the proportion of plastic molds will continue to rise. At the same time, the increasing complexity and precision of mechanical parts also put forward higher requirements for plastic molds. The technological content of injection molds will continue to increase, and the proportion of mid- to high-end molds will gradually increase to meet the market demand for high-quality and high-precision molds.

3. Delivery Time Trend: Standardization Accelerates Production Cycles

The application of standard components for injection molds will become more widespread. The standardization of molds and the use of standard components will greatly affect the manufacturing cycle of molds. The adoption of standard mold components not only shortens the manufacturing cycle of molds but also improves mold quality and reduces costs. Therefore, the application of standard mold components is bound to become more prevalent, such as plastic mold bases, ejector pins, sleeve pins, screws, and springs, which will all form standardized components.

In summary, the medical injection mold manufacturing industry is rapidly developing towards technological innovation, high precision, and standardization. Dongguan Yize Mold Co., Ltd., as a company engaged in precision mold design and manufacturing as well as precision injection molding product production for many years, focuses on providing a complete set of solutions for automotive connectors, medical product injection molding, cleanroom injection molding, PFA custom injection molding, and other products. The company is headquartered in Dongguan, the manufacturing capital, with convenient transportation and logistics. We welcome friends from all walks of life to call for consultations (+86 13302615729, same number for WeChat and WhatsApp) to jointly explore the future path of medical injection mold manufacturing.

Home

Home