Recently, a client from the medical device industry approached Yize Injection Molding Factory, inquiring about our unique advantages as a professional manufacturer of medical plastic products. In this article, Yize's editor will elaborate on the advantages of processing and molding medical plastic products.

Plastic processing and molding is a technology widely used in various fields, with its core processes including rubber injection molding and plastic injection molding. Among them, injection molding can be further divided into compression molding and die-casting methods. Injection molding machines are the primary equipment for processing thermoplastic or thermoset materials into plastic products of various shapes. They work through the synergistic effect of injection molding machines and molds to achieve plastic molding.

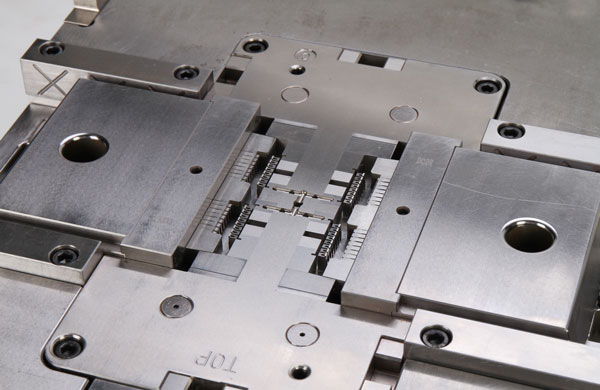

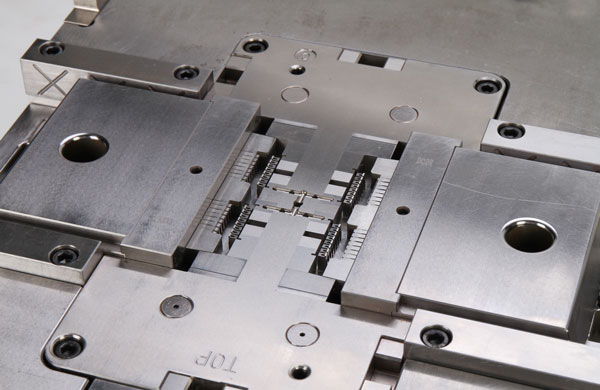

In the injection molding process, two essential components play a crucial role: one is the injection unit, which is responsible for melting the plastic before it is injected into the mold, and controlling the pressure and speed to precisely inject the molten material into the mold; the other is the mold itself, which must remain closed under the injection pressure to ensure the quality of the plastic products.

The reason why plastic processing and molding technology is highly favored is mainly due to its many advantages. Among them, the constant quality of the molten material, the high pressure and high-speed injection process, and the precise control of the injection volume are key factors in ensuring the quality of plastic products.

As a leader in the field of medical plastic product processing and molding, Yize Mold not only focuses on customizing precision medical molds and medical injection molding products, but our products are also widely used in various fields such as household automotive connectors, medical device injection molding components, and special material injection molding. After years of technological accumulation and refinement, we have successively obtained ISO9001, ISO14001, and IATF16949 quality system certifications, and our strength has been widely recognized by the industry.

It is worth mentioning that since its establishment in 2007, Dongguan Yize Mold Co., Ltd. has been adhering to the corporate philosophy of "Professionalism, Precision, and Innovation". Headquartered in Dongguan, the manufacturing capital, with convenient transportation and logistics, we have many years of experience in precision mold design and manufacturing, as well as precision injection molding product production. The company specializes in the design, precision mold manufacturing, injection molding and assembly, and after-sales service of products such as automotive connectors, medical product injection molding, cleanroom injection molding, PFA custom injection molding, providing a complete set of solutions.

If you have any questions or needs regarding the processing and molding of medical plastic products, please feel free to contact us at any time. Contact number: +86 13302615729 (WeChat, WhatsApp same number). Yize Mold looks forward to creating a better future with you!

Home

Home