Medical mould manufacturing involves injecting molten plastic into a mould through a spraying process to form the desired shape. Before engaging in medical mould manufacturing, a series of questions need to be addressed. Here are the key considerations for medical mould manufacturing:

-

Product Design Requirements: It is necessary to understand the design requirements of the product, including dimensions, shape, appearance, and material requirements. This has a significant impact on the size and shape of the mould to ensure the quality of the injected product. Therefore, product drawings and samples are indispensable in the manufacturing process.

-

Material Selection: Based on the product design requirements, a suitable injection moulding material needs to be selected. Different materials have different characteristics, such as hardness, toughness, and high-temperature resistance. Choosing the right material can enhance the performance and durability of the product.

-

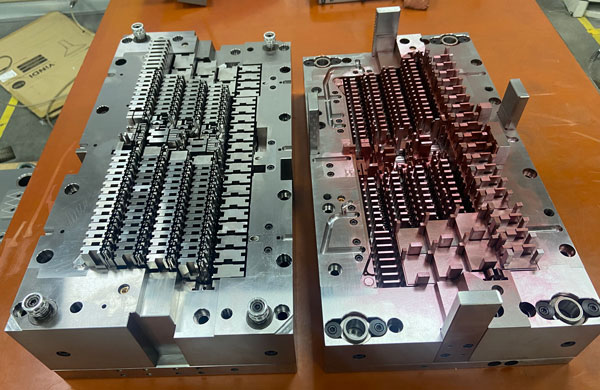

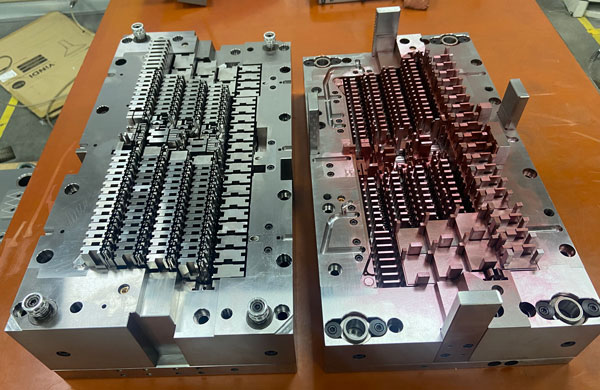

Mould Design: Detailed mould design is required before medical mould manufacturing. This includes the mould structure, components, mould opening method, ventilation method, etc. The quality of mould design directly affects product quality and production efficiency.

-

Mould Material Selection: When manufacturing medical moulds, appropriate materials need to be selected. Common mould materials include tool steel and stainless steel. Choosing suitable materials can improve the wear resistance and corrosion resistance of the mould, extending its service life.

-

Mould Manufacturing Process: Mould manufacturing is a relatively complex process, including CNC machining, wire cutting, electrical discharge machining, etc. The precision and quality of mould manufacturing directly affect the dimensions and shape of the product.

-

Mould Machining Precision: The mould manufacturing process needs to consider the machining precision of the mould. The higher the machining precision of the mould, the better the dimensional stability and consistency of the product.

-

Mould Trial and Debugging: After manufacturing the mould, trial and debugging are required. This includes mould assembly, adjustment, nozzle design, and parameter settings. Only through good mould trial and debugging can good injection results be achieved.

-

Mould Maintenance and Care: Medical moulds are tools for long-term use, so regular maintenance and care are necessary. Cleaning, lubricating, and repairing the mould can extend its service life and reduce production costs.

-

Mould Quality Control: Strict quality control is required during the medical mould manufacturing process. This includes dimension measurement, material testing, and product testing. Only through good quality control can product quality be ensured.

-

Mould Storage and Management: Medical moulds need to be stored and managed before and after use. Mould storage should avoid external environmental influences and damage, and mould management requires recording and tracking for timely location and management.

The above are the key considerations that need to be understood in the medical mould manufacturing process. Accurate understanding and handling of these issues can improve the efficiency and quality of medical mould manufacturing. To meet customer needs, Yize Mould Co., Ltd., as a leader in the plastic manufacturing industry, relies on its development and production capabilities to provide high-quality medical plastic products to customers in various industries.

Home

Home