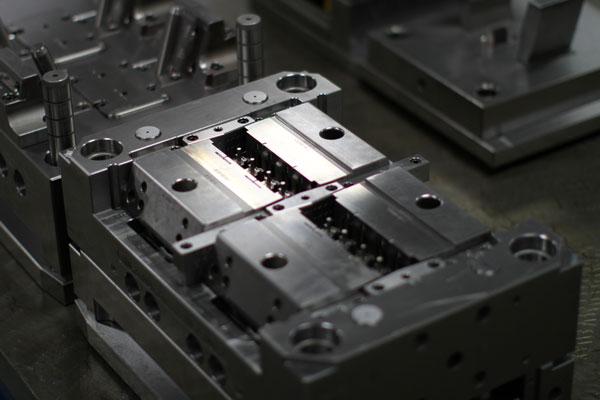

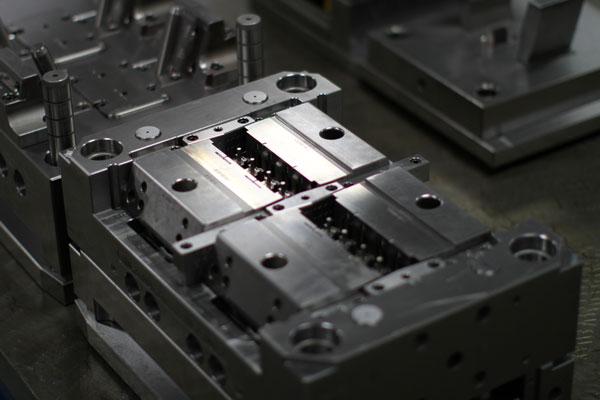

In the medical field, plastic products are widely used, ranging from disposable syringes and infusion sets to various precise medical instrument shells, all of which rely on medical injection molded parts. As the key tool for manufacturing these injection molded parts, medical plastic molds have long been a topic of great concern in the industry regarding whether their manufacturing structure will affect the forming and processing defects of medical injection molded parts. Today, let's delve into this issue.

The Intricate Connection Between Mold Structure and Injection Molded Part Defects

Unreasonable Runner System Design

The runner system is the channel through which plastic melt flows from the nozzle of the injection molding machine into the mold cavity. If the runner design is unreasonable, such as having a too - small runner diameter, it will increase the resistance during the flow of the plastic melt, resulting in significant pressure loss. As a result, the melt may experience insufficient filling when filling the cavity, leading to defects like material shortage and dents on the surface of the injection molded part. On the contrary, if the runner diameter is too large, although it can reduce the flow resistance, it will cause waste of plastic materials and also prolong the cooling time, affecting production efficiency. In addition, the layout of the runner also affects the uniformity of the melt flow. An improper layout may cause inconsistent flow speeds of the melt in the cavity, thus generating weld lines on the injection molded part, affecting its strength and appearance quality.

Defects in Gate Design

The gate is a narrow channel connecting the runner and the cavity, and its function is to control the flow speed and direction of the melt. If the gate size is too large, it will make the melt enter the cavity too fast, causing a jet phenomenon, which leads to defects such as air bubbles and shrinkage cavities inside the injection molded part. If the gate size is too small, it will increase the flow resistance of the melt, making it difficult to fill the cavity, and also resulting in insufficient filling. In addition, the selection of the gate position is also crucial. If the gate position is improper, it may cause dead corners in the melt flow within the cavity, making it difficult for the plastic material to fully fill the cavity or causing warpage and deformation of the injection molded part after demolding.

Imperfect Cooling System

Medical injection molded parts need to be rapidly cooled and solidified during the forming process to ensure dimensional accuracy and performance. If the mold's cooling system design is imperfect, such as having unevenly distributed cooling water channels, it will lead to local overheating or undercooling of the mold. High temperatures will slow down the cooling of the plastic melt, prolonging the molding cycle and possibly causing defects such as uneven shrinkage and deformation of the injection molded part. Low temperatures will make the plastic melt solidify too early, affecting the fluidity of the melt and also resulting in insufficient filling. In addition, blockages or leaks in the cooling water channels will also affect the cooling effect and thus the quality of the injection molded part.

Improper Ejection System Design

The ejection system is used to eject the injection molded part from the mold after it is formed. If the ejection system design is improper, such as having an insufficient number of ejector pins, improper positions, or uneven ejection forces, it will cause deformation or cracking of the injection molded part during the ejection process. Especially for thin - walled and complex - shaped medical injection molded parts, the design of the ejection system requires more caution. The positions of the ejector pins should be selected at the stronger parts of the injection molded part, and the ejection force should be evenly distributed to avoid damaging the injection molded part.

Real - Life Cases Reveal the "True Colors" of Structural Defects

A medical device manufacturer encountered frequent surface defects such as weld lines and air bubbles in the production of pistons for disposable syringes. After a careful inspection of the mold, it was found that there were problems with the runner system and gate design. The original mold had a too - small runner diameter and an improper gate position, which increased the flow resistance and uneven speed of the plastic melt, resulting in weld lines and air bubbles. Later, the manufacturer improved the mold by enlarging the runner diameter and optimizing the gate position. After trial molding and adjustments, the defect problems of the product were effectively solved, and both production efficiency and product quality were significantly improved.

Countermeasures: Optimize Mold Structure to Improve Injection Molded Part Quality

Scientifically Design the Runner and Gate

When designing the runner and gate, it is necessary to fully consider factors such as the characteristics of the plastic material, the shape and size of the injection molded part, and the parameters of the injection molding machine. Computer simulation software can be used to optimize the design of the runner and gate, predict the flow situation of the melt, and thus determine the optimal runner diameter, length, gate size, and position. At the same time, efforts should be made to reduce the length and the number of bends in the runner to lower the flow resistance.

Improve the Cooling System

The design of the cooling system should be reasonably arranged according to the structure of the mold and the shape of the injection molded part. It is necessary to ensure that the cooling water channels can evenly cover all parts of the mold to maintain a uniform mold temperature. Series, parallel, or hybrid layouts of the cooling water channels can be adopted to improve the cooling efficiency. In addition, the cooling water channels should be regularly cleaned and maintained to prevent blockages and leaks.

Reasonably Design the Ejection System

The design of the ejection system should be based on the shape, size, and demolding requirements of the injection molded part. The number, position, and diameter of the ejector pins should be reasonably determined to ensure an even distribution of the ejection force. For injection molded parts with complex shapes, auxiliary ejection mechanisms such as inclined ejectors and slides can be used to ensure that the injection molded part can be smoothly ejected without damage.

Conclusion

The manufacturing structure of medical plastic molds has a crucial impact on the forming and processing defects of medical injection molded parts. An unreasonable mold structure may lead to various defects such as insufficient filling, weld lines, air bubbles, and deformation in the injection molded parts, affecting the product's quality and performance. Therefore, in the mold design and manufacturing process, various factors should be fully considered, the mold structure should be optimized, and scientific design methods and advanced manufacturing technologies should be adopted to improve the quality and production efficiency of medical injection molded parts. Only in this way can safer and more reliable plastic products be provided for the medical industry to safeguard people's health and lives.

It is hoped that this article can help you understand the relationship between the manufacturing structure of medical plastic molds and the forming and processing defects of medical injection molded parts. If you have any other questions about medical plastic molds or injection molded parts, feel free to leave a comment in the discussion area.

Home

Home