I. Production Process of Injection-Molded Medical Products

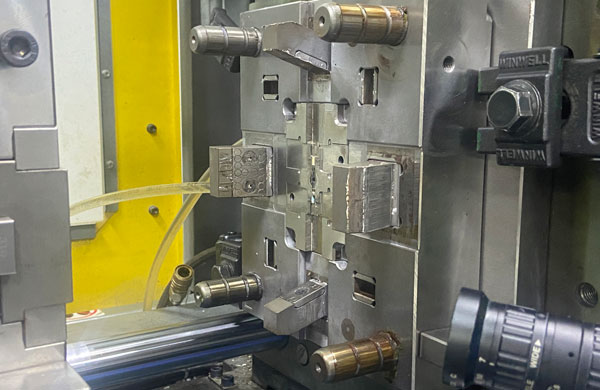

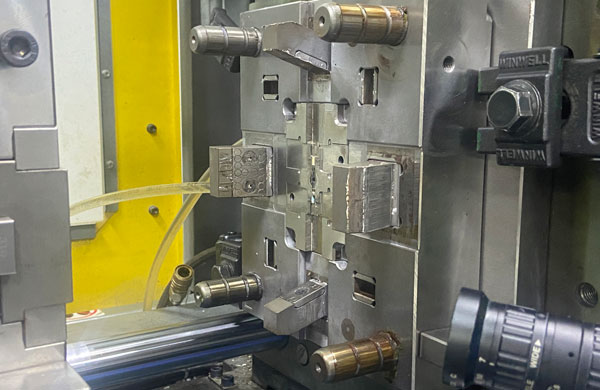

The production and processing of injection-molded medical products is a meticulous and systematic process that relies on the synergy of injection molding machines and precision molds. The entire production process begins with the preparation of high-quality raw materials, followed by a series of complex procedures such as plastic melting, injection, pressure holding, cooling, and ultimately product ejection. Throughout this process, parameters such as temperature and time at each stage must be strictly controlled to ensure product quality and precision.

1. Preparation

Prior to injection molding, it is essential to prepare high-quality raw materials, injection molding machines, and precisely designed molds. Additionally, comprehensive adjustments and testing of the equipment are required to ensure smooth production.

2. Production Process of Injection-Molded Products

The injection molding process can be subdivided into multiple stages, including plastic melting, injection, pressure holding, cooling, and final product ejection. Each stage has its specific process requirements, such as ensuring complete melting and uniform temperature of the plastic during the melting stage, and controlling injection speed and pressure during the injection stage to avoid product defects.

3. Product Inspection and Packaging

After production, the products undergo rigorous inspection and packaging. This step is crucial for ensuring product integrity and usage safety. During inspection, the appearance, dimensions, and performance of the products are comprehensively tested to ensure they meet quality standards. Packaging must consider the transportation and storage needs of the products to prevent damage during transit.

II. Applications of Injection-Molded Medical Products

Due to their efficient and precise production methods, injection-molded medical products are widely used in the medical field. From daily-use medical gloves and infusion sets to more specialized venous blood collection needles and syringes, injection-molded medical products have become an indispensable part of the modern medical system. They not only improve the efficiency of medical work but also greatly ensure patient safety.

III. Optimization Strategies

To further enhance the quality and competitiveness of injection-molded medical products, optimization is needed from multiple aspects. Firstly, production parameters and process flows should be continuously optimized to improve product quality and precision. Secondly, emphasis should be placed on product functionality and human-centered design to meet the diverse needs of medical personnel and patients. Furthermore, strengthening quality control and cost management is essential to ensure that products maintain a reasonable price advantage while guaranteeing quality.

In summary, the production and processing of injection-molded medical products is a complex and meticulous process, with wide-ranging and important applications in the medical field. By continuously optimizing production processes, strengthening quality control, and focusing on human-centered design, we can provide the medical field with more high-quality, efficient injection-molded medical products.

Home

Home