Introduction

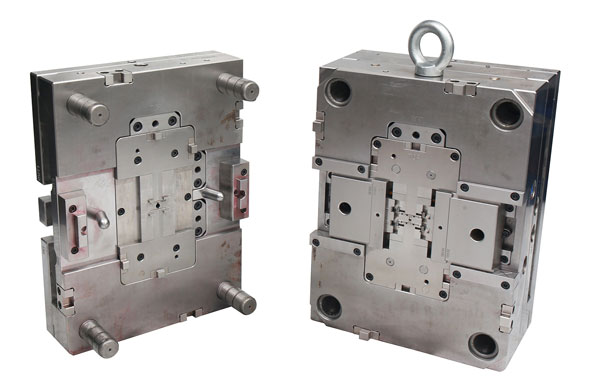

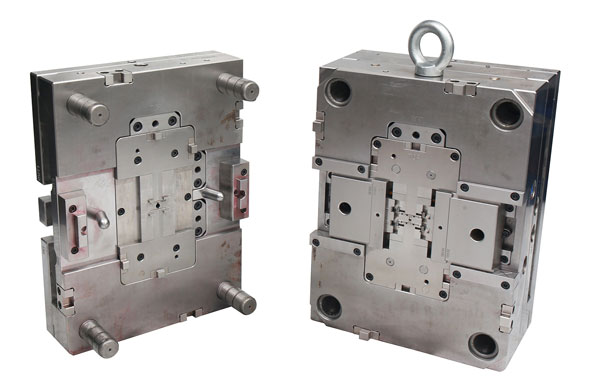

In the grand landscape of modern industrial manufacturing, injection molds are like a brilliant star, playing a wide - ranging and crucial role. They are like a magical "shape - giving master". From the daily necessities within our easy reach to the cutting - edge products in the high - tech field, injection molds are silently making significant contributions behind the scenes. Among various industries, the medical industry relies particularly heavily on injection molds. Next, let's focus on the key area of the medical industry and delve into the specific applications and remarkable advantages of injection molds.

Applications and Advantages of Injection Molds in the Medical Industry

Diverse Application Scenarios

Injection molds have extremely wide applications in the medical industry, like a fine - meshed net covering numerous medical products. In terms of medical consumables, items such as syringes, infusion sets, and medical catheters, which are common and vital in hospitals, all rely on injection molds for production. At the same time, some medical devices also depend on injection molds, such as the casings of small diagnostic equipment and handheld medical instruments. They achieve precise shaping and stable performance with the help of injection molds.

Stringent Special Requirements

-

Biocompatibility: The medical industry has extremely high safety requirements for materials. The materials used in injection molds must have excellent biocompatibility. This is like putting on a "safety armor" for medical products to ensure that they do not cause any adverse effects when in contact with the human body. Therefore, medical - grade materials that have undergone strict testing and certification are usually selected, such as medical - grade polycarbonate and polypropylene. These materials are like "elite guards" that have passed multiple levels of screening, safeguarding patients' health.

-

Aseptic Production: Asepsis is of utmost importance in the production of medical products. The design and manufacturing of injection molds must fully consider the need for easy cleaning, disinfection, and sterilization. Their structure should be as simple as possible to avoid cleaning dead corners, just like a clean and bright room with no hidden places for dirt. In addition, a detachable design is also a common method to ensure that the produced medical products meet aseptic standards and provide safety guarantees for patients' treatment.

-

Precision and Reliability: Medical products have almost stringent requirements for dimensional accuracy and quality stability. The dimensional accuracy of injection molds needs to be controlled within ±0.02mm, which is like precise "carving" in the microscopic world. Moreover, the molds should not deform or crack during long - term use to ensure that each produced medical product has consistently high quality, thus guaranteeing the medical effect.

Significant Advantages

-

Ensuring Patient Safety: The medical products produced by injection molds are highly consistent in terms of size, shape, and performance, like a group of well - trained "soldiers" in neat formation. This stability ensures the reliability of medical quality. For example, the scales on syringes are accurate, and the flow rates of infusion sets are stable, which can provide a solid guarantee for patients' treatment and make patients feel more at ease when receiving treatment.

-

Improving Production Efficiency: In the medical industry, there are relatively high requirements for the speed and quantity of product supply. Injection molds can achieve large - scale and rapid production, like an efficient "production machine", meeting the industry's demand for large and fast supply. Especially in response to public health emergencies, they can quickly provide a large number of medical products to provide strong support for combating epidemics and other emergencies.

-

Reducing Costs: Large - scale production is one of the major advantages of injection molds. By spreading the costs, it can effectively reduce the production cost per unit. At the same time, the injection production process has a high degree of automation, which reduces human intervention. This not only lowers labor costs but also improves the product qualification rate and reduces the defect rate, further reducing production costs and bringing considerable economic benefits to medical enterprises.

Conclusion

In summary, the application advantages of injection molds in the medical industry are very significant. With their high - precision production capacity, they meet the strict quality requirements of the medical industry for products; with their diverse applications, they adapt to the production needs of different products in the medical industry; with their guarantee of patient safety, they have won the trust of medical practitioners and patients; with their cost - reducing advantages, they provide strong support for the development of medical enterprises. With the continuous progress of technology, injection molds and their manufacturing technology will surely continue to innovate and optimize, playing a more critical role not only in the medical industry but also in various other industries. Their future development prospects are very bright and worth looking forward to.

Home

Home