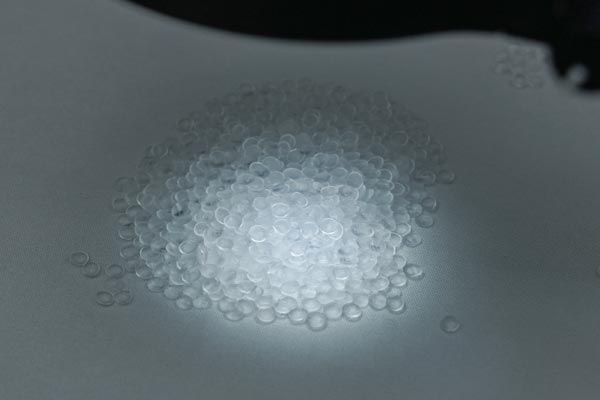

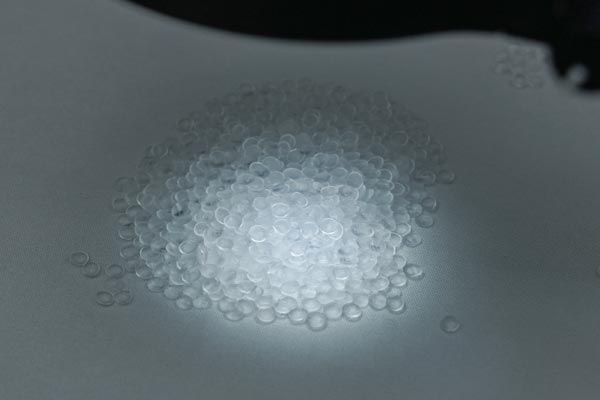

In the medical industry, injection molding is widely used to manufacture various precision medical device components, ranging from disposable syringe and infusion set parts to complex surgical instrument handles. The selection of raw materials for medical injection molding is far from a simple material - picking process. It directly relates to the quality, performance, safety of medical devices, as well as the health and life safety of patients. Its importance is reflected in several key aspects.

Ensuring the Basic Performance of Medical Devices

The physical and chemical properties of raw materials for medical injection molding are the foundation for determining whether medical devices can function properly. Different medical devices have specific requirements for properties such as the strength, hardness, toughness, wear resistance, and corrosion resistance of raw materials. For example, the pistons and syringe barrels of disposable syringes require raw materials with sufficient strength and toughness to ensure that they do not break or deform during the process of injecting medicine. At the same time, they need good wear resistance to prevent the generation of tiny particles due to friction during multiple uses or storage, which could affect the quality of the medicine. If the selected raw materials have insufficient strength, the piston may break during medicine injection, leading to medicine leakage. This not only fails to complete the injection task but may also harm the patient. If the raw materials lack toughness, the syringe barrel may break under slight external force, disrupting the medical operation.

For some medical devices that need to be implanted in the human body for a long time, such as artificial joints and heart stents, the requirements for raw material properties are even more stringent. These devices have to withstand the complex mechanical and chemical environments inside the human body, so the raw materials must have extremely high strength, fatigue resistance, and corrosion resistance. Take artificial joints as an example. They need to bear long - term pressure and friction at human joint sites. If the wear resistance of the raw materials is poor, the joint surface will gradually wear away, producing metal debris. These debris may trigger an immune response in the human body, causing inflammation and pain around the joint, and even affecting the normal function of the joint, shortening the service life of the artificial joint and subjecting the patient to the pain and economic burden of a second operation.

Guaranteeing the Biological Safety of Medical Devices

Medical devices come into direct or indirect contact with the human body, so the biological safety of their raw materials is of utmost importance. Qualified raw materials for medical injection molding must meet strict biocompatibility standards and should not cause adverse reactions such as irritation, allergies, or toxicity to human tissues. If raw materials with sub - standard biological safety are used in the medical injection molding process, harmful substances such as heavy metal ions, organic solvent residues, and monomers may be released. These substances can enter the human body and trigger an immune system response, leading to diseases such as allergies and inflammation. In severe cases, they may even damage human organs and systems, endangering life.

For example, some low - quality plastic raw materials may contain excessive plasticizers. These plasticizers will gradually migrate out during the use of medical devices and enter the human body. Long - term exposure or ingestion of plasticizers may have adverse effects on the human endocrine and reproductive systems, especially for sensitive populations such as children, pregnant women, and the elderly. In addition, heavy metal residues in raw materials, such as lead, mercury, and cadmium, have cumulative properties. They will gradually accumulate in the human body and, when reaching a certain dose, can cause damage to the nervous system, digestive system, and kidneys. Therefore, selecting raw materials with high biological safety is the fundamental prerequisite for ensuring the safe use of medical devices.

Affecting the Processing Technology and Finished Product Quality of Medical Devices

Different raw materials for medical injection molding have different processing characteristics, such as melting temperature, fluidity, and shrinkage rate. These characteristics directly affect the parameter settings and molding effects of the injection molding process. If the raw materials are improperly selected, various problems may occur during the injection molding process, such as insufficient filling, shrinkage, flash, and bubbles, which affect the appearance quality and dimensional accuracy of medical devices.

For example, some raw materials have poor fluidity. During injection molding, it is difficult for them to fully fill the mold cavity, often resulting in insufficient filling. This leads to defects such as depressions and material shortages on the product surface, affecting the product's sealing and functionality. Raw materials with a large shrinkage rate will undergo significant dimensional shrinkage after molding, making it difficult to control the dimensional accuracy of the product and failing to meet the precise dimensional requirements of medical devices. In addition, the processing characteristics of raw materials also affect the injection molding cycle and production efficiency. If the melting temperature of the raw materials is too high or their fluidity is poor, the heating time and injection time need to be extended, thus reducing production efficiency and increasing production costs.

Complying with Regulations and Standards

The medical industry is subject to strict regulatory and standard supervision, with clear regulations on the use of raw materials for medical devices. Regulatory authorities in various countries have formulated relevant laws and standards, requiring medical device manufacturers to use raw materials that meet the requirements for production. These laws and standards not only specify indicators such as the chemical composition, physical properties, and biological safety of raw materials but also strictly regulate the procurement, storage, and use of raw materials.

Selecting raw materials that comply with laws and standards is a prerequisite for medical devices to obtain market access and be legally sold. If an enterprise uses unqualified raw materials to reduce costs, not only will the product fail to pass the approval of regulatory authorities but the enterprise may also face legal liability and reputation damage. At the same time, with the continuous development of the global medical market and the increasingly strict regulatory requirements, the quality and safety requirements for raw materials for medical injection molding are also constantly improving. Only by selecting high - quality raw materials can enterprises adapt to market changes, meet customer needs, and remain competitive in the fierce market competition.

Selecting the right raw materials for medical injection molding is a crucial link in the manufacturing process of medical devices. It not only relates to the basic performance, biological safety of medical devices but also affects the processing technology and finished product quality. Moreover, it involves regulatory compliance. Medical enterprises must attach great importance to the selection of raw materials, strictly control the quality of raw materials, and ensure the quality and safety of medical devices from the source, providing reliable protection for the health and life safety of patients.

Home

Home