In the field of injection molding, thin-wall injection molding places extremely stringent and specific requirements on injection molds due to its unique application needs. So, what kind of injection molds can meet the demands of thin-wall injection molding? This requires us to analyze the mold's adaptability in several key aspects based on the characteristics of thin-wall injection molding.

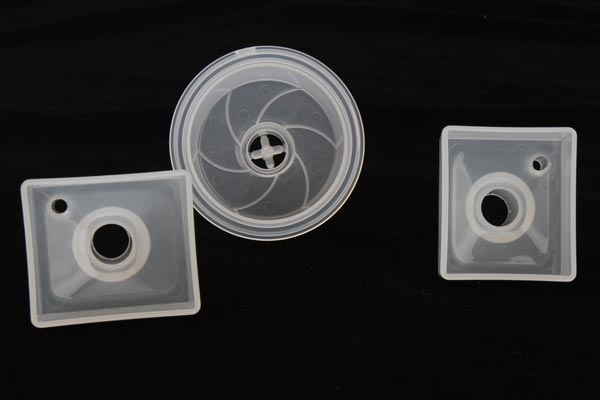

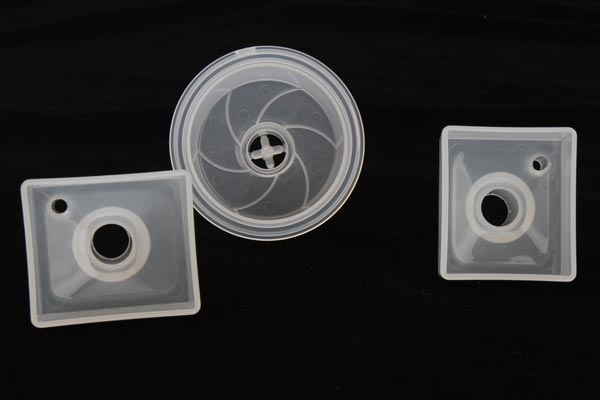

Firstly, clarifying the concept of thin-wall injection molding is the foundation for understanding its mold requirements. Thin-wall injection molding has important applications in the medical field, with a typical feature of product wall thickness being less than 1mm. It differs significantly from ordinary injection molding. In terms of process parameters, it requires higher injection pressure and speed, shorter cooling time, and also necessitates changes in the ejection method and gate arrangement of plastic products. These differences determine that thin-wall injection molds must possess unique designs and performances.

Injection speed is one of the key factors for the success of thin-wall injection molding. During thin-wall injection molding, rapid mold filling and high pressure are crucial. High speed can quickly inject the molten thermoplastic material into the mold cavity, effectively preventing gate solidification. If the injection speed is insufficient, the molten material may solidify prematurely at the gate, resulting in incomplete product filling and defects. Therefore, mold design must fully consider how to optimize the runner structure to reduce the flow resistance of the material, so as to adapt to the requirements of high-speed injection and ensure that the material can smoothly and quickly fill the mold cavity.

In terms of mold material selection, P20 steel, which is widely used in the manufacture of molds for traditional products, is difficult to meet the high-pressure requirements of thin-wall injection molding. Due to the higher pressure required in thin-wall injection molding, the mold must be made of extremely sturdy steel. H-13 steel and other hard steels are ideal choices as they can build a more robust mold structure for thin-wall molds and withstand the huge stress during high-pressure injection molding, ensuring the stability and service life of the mold. However, using these high-quality steels also means an increase in the cost of the mold. But in the long run, their reliability and durability can bring higher benefits to production.

The cooling system is also an important part of the design of thin-wall injection molds. Thin-wall injection molding has a significant advantage. When the thickness of medical plastic products decreases, the amount of material that needs to be cooled also decreases. As the thickness decreases, the molding cycle can be significantly shortened, theoretically even by half. To further optimize the molding cycle, using hot runner systems and runner bushings is an effective method. The hot runner system can precisely control the temperature and flow of the plastic melt, reduce heat loss, and enable the material to cool evenly in the mold cavity. Runner bushings can optimize the gate design and improve the filling efficiency of the material, thus helping to shorten the molding cycle and enhance production efficiency.

In conclusion, injection molds that meet the requirements of thin-wall injection molding need to reach high standards in terms of injection speed adaptation, sturdy material selection, and cooling system optimization. Only in this way can they ensure product quality, improve production efficiency, and meet the demands for high-precision and high-performance plastic products in the medical and other fields.

Home

Home