In the medical industry, product precision, safety, and production efficiency directly impact patient health and safety. Injection molding, a core manufacturing process for medical products (e.g., syringes, catheter connectors, surgical instrument components), demands not only advanced equipment and technology but also seamless collaboration across design and production stages. Achieving this integration is critical for enhancing product quality, shortening development cycles, and reducing costs.

1. Unique Challenges in Medical Injection Molding: Precision and Compliance

Medical injection-molded products face stricter requirements than industrial counterparts:

-

Material Compliance: Must meet biocompatibility standards (e.g., ISO 10993), sterilization resistance (e.g., EO, gamma radiation), and chemical stability.

-

Precision and Complexity: Micron-level tolerances (e.g., ±0.01mm) and intricate geometries (e.g., multi-cavity, thin-walled parts) demand advanced mold design and injection processes.

-

Cleanroom Production: Requires ISO Class 8 or higher cleanrooms to prevent particulate contamination.

-

Regulatory Compliance: Must pass certifications like FDA and CE with full traceability.

These challenges necessitate breaking down information silos between design and production teams.

2. Core Enabler: Design for Manufacturing (DFM) Philosophy

1. Early-Stage Manufacturability Reviews

-

Use simulation tools (e.g., Moldflow) to predict filling, cooling, and warping issues, optimizing gate placement, runner design, and ejection systems.

-

Select materials based on functional requirements (e.g., transparency, flexibility) and sterilization methods, avoiding costly late-stage changes.

-

Define critical tolerances (e.g., ±0.01mm) and surface finishes (e.g., Ra ≤ 0.8μm) upfront.

2. Cross-Departmental Collaboration Platforms

-

Establish unified teams comprising designers, mold engineers, process experts, and quality inspectors using shared CAD/PLM systems for real-time data synchronization.

-

Validate ergonomics and assembly compatibility through 3D-printed prototypes before mass production.

3. Production-Side Efficiency: Smart and Flexible Manufacturing

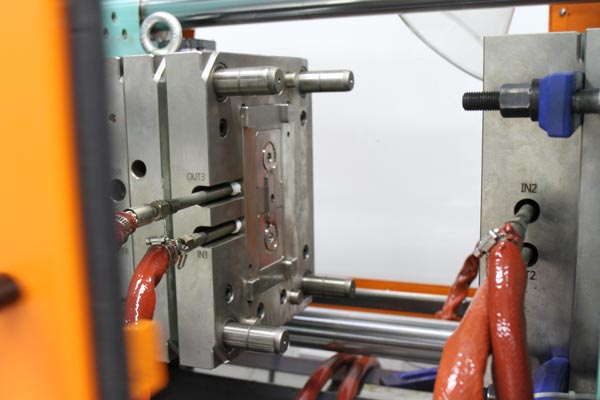

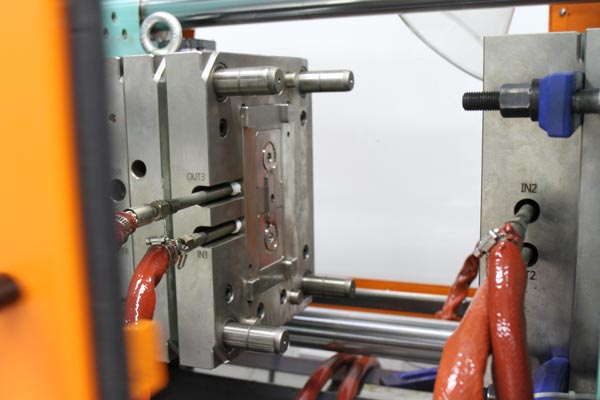

1. Precision Mold Design and Fabrication

-

Achieve ±0.005mm mold cavity accuracy using high-speed milling, EDM, and laser texturing.

-

Integrate IoT sensors for real-time mold condition monitoring (e.g., temperature, wear) to enable predictive maintenance.

2. Intelligent Injection Process Control

-

Deploy closed-loop systems to dynamically adjust pressure, temperature, and speed parameters, ensuring CPK ≥ 1.33 for batch consistency.

-

Adopt advanced techniques like multi-component or gas-assisted injection molding for complex structures (e.g., soft-hard combinations).

3. Automation and Cleanroom Protocols

-

Use robotic arms for automated picking, inspection, and packaging to minimize human contamination risks.

-

Combine laminar flow systems with ISO Class 8 cleanroom designs to control particles ≥0.5μm at ≤3,520,000/m³.

4. Quality Control: Full Traceability and Continuous Improvement

1. In-Line Inspection and Data Capture

-

Implement AOI and laser measurement systems for 100% critical dimension checks, with data uploaded to MES platforms in real time.

-

Use SPC analysis to identify process variations and optimize parameters.

2. Traceability and Compliance Management

-

Apply RFID/QR codes for end-to-end traceability from raw material batches to finished product serial numbers.

-

Conduct regular internal audits and third-party certifications (e.g., ISO 13485) to meet regulatory demands.

5. Case Study: Seamless Integration for a Medical Catheter Connector

A company achieved this through:

-

Design Phase: Optimized gate placement via Moldflow simulation to eliminate weld lines affecting seal integrity; selected gamma-resistant PC material.

-

Mold Fabrication: Used high-speed milling for cavity machining with hard chrome coating for wear resistance.

-

Production Phase: Deployed a 5-axis robot for integrated picking/assembly and in-line vision inspection, reaching 99.97% first-pass yield.

-

Lead Time: Reduced development cycle from design to mass production to 8 weeks (40% faster than traditional methods).

6. Future Trends: Digitalization and Sustainability

-

Digital Twin Technology: Accelerate mold development through virtual commissioning and reduce trial costs.

-

AI-Driven Process Optimization: Leverage machine learning to analyze historical data and auto-generate optimal injection parameters.

-

Green Manufacturing: Adopt bio-based materials and recycled blends to minimize environmental impact.

Conclusion

Seamless integration in medical injection molding hinges on aligning design and manufacturing logic. By adopting DFM principles, intelligent technologies, and end-to-end quality control, companies can meet stringent medical requirements while achieving cost efficiency. Future advancements in digitalization will drive further flexibility, intelligence, and sustainability in medical manufacturing.

Home

Home