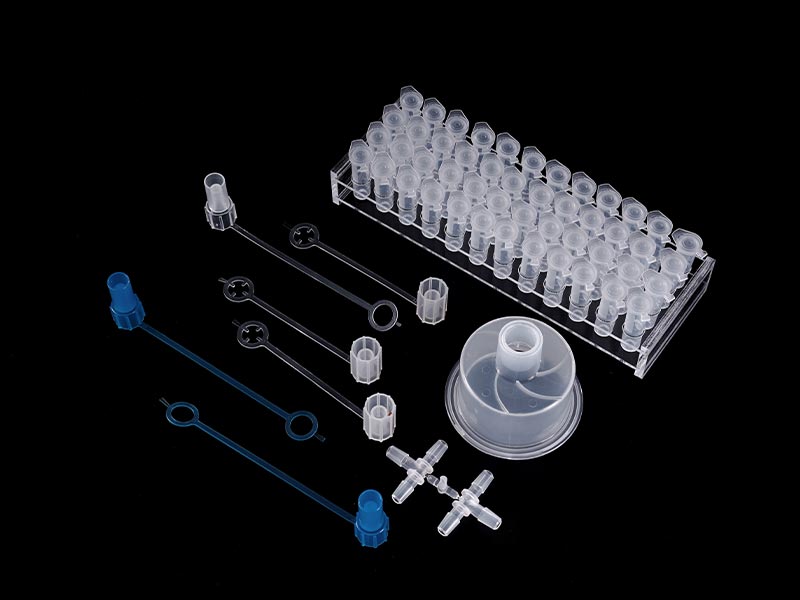

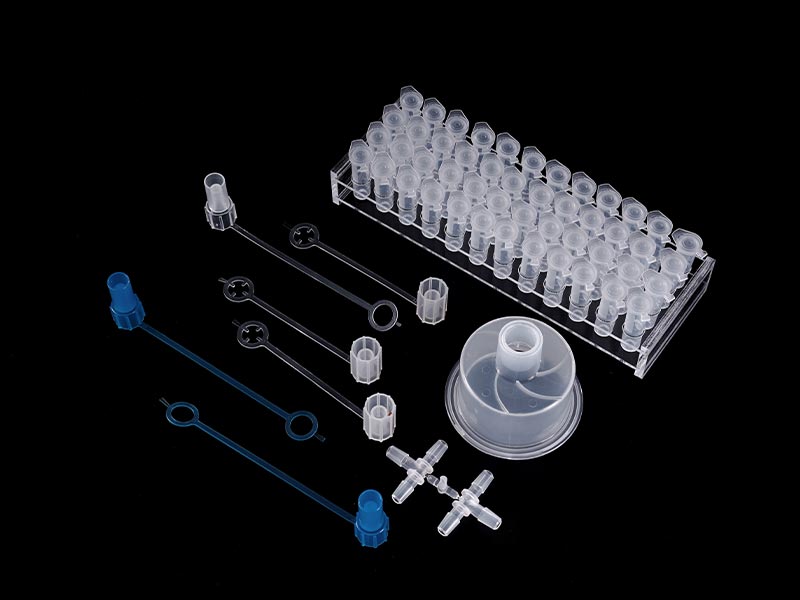

A medical consumables injection molding factory specializes in producing high-quality plastic components and devices used in the medical field. These factories manufacture products such as syringes, IV connectors, catheters, test tube caps, and other single-use medical devices. Here's an overview of such a facility:

Key Features of a Medical Injection Molding Factory

1.Clean Room Facilities

-

Adheres to ISO 13485 and other medical manufacturing standards.

-

Class 7 or Class 8 clean rooms to minimize contamination.

2.Specialized Equipment

-

High-precision injection molding machines.

-

Micro-molding technology for intricate designs.

-

Automated systems for increased production efficiency.

3.Materials Used

-

Medical-grade polymers (e.g., polypropylene, polycarbonate, silicone, and TPU).

-

Materials certified for biocompatibility and sterilization methods like gamma radiation or ETO sterilization.

4.Certifications & Standards

-

ISO 13485 for medical devices.

-

FDA registration for products used in regulated markets.

-

GMP (Good Manufacturing Practices) compliance.

5.Common Products Manufactured

-

Syringes, infusion sets, and needle hubs.

-

Vials, bottles, and closures.

-

Surgical instruments or parts (scalpels, retractors).

-

Diagnostic tools and consumables (pipette tips, Petri dishes).

6.Quality Control

-

Rigorous quality assurance protocols including in-line inspections, mold validation, and biocompatibility testing.

-

Advanced measurement tools for precise dimensions and tolerances.

7.Sustainability Practices

-

Waste management and recycling of rejected plastics.

-

Energy-efficient machines to reduce carbon footprint.

8.Advantages of Medical Injection Molding

-

Precision: Essential for devices with stringent tolerances.

-

Scalability: Suitable for mass production of disposable medical items.

-

Cost-Efficiency: Lower cost per unit for large-volume runs.

-

Design Flexibility: Capable of producing complex geometries.

If you're planning to start or source from such a factory, understanding these essentials will help ensure high-quality and regulatory-compliant production. Would you like assistance with specific information, such as finding suppliers or setting up a facility?

Home

Home