In the medical industry, injection-molded parts serve as core components of medical devices, directly impacting patient safety and treatment efficacy. From precision insulin syringe components to complex hemodialyzer housings, the production of medical injection-molded parts must meet stringent requirements for accuracy, reliability, and biocompatibility. This article systematically explores key management aspects in medical injection molding from three dimensions: the construction of a full-process quality control system, identification of critical defect types, and corresponding prevention strategies.

1. Construction of a Full-Process Quality Control System

1.1 Clean Production Environment Control

Medical injection molding workshops must adhere to ISO Class 7 (10,000-level) cleanroom standards, with temperature (20–25°C), humidity (40–60%), and particulate counts (≤352,000 particles/m³) strictly regulated. For example, when producing pacemaker housings, workshops employ laminar flow systems, airlocks, and HEPA filters to block microbial contamination, while banning silicone-based mold release agents to avoid residue affecting biocompatibility.

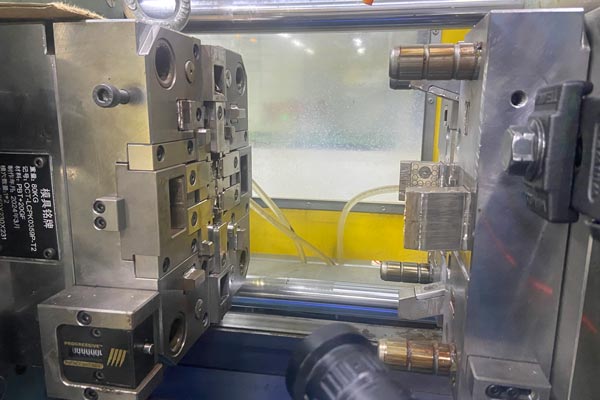

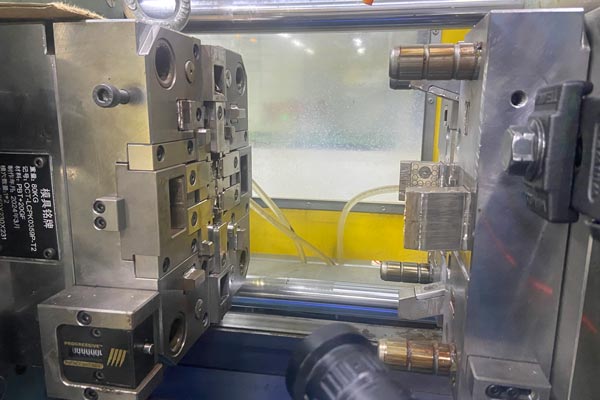

1.2 Precision Verification of Equipment and Molds

-

Injection Molding Machines: Medical-grade equipment with closed-loop control systems ensures injection pressure fluctuations ≤±5% and temperature precision ±1°C. For instance, producing PEEK orthopedic implants requires servo-driven screw mechanisms to eliminate hydraulic oil contamination risks.

-

Molds: Fabricated using five-axis machining centers, critical dimensions achieve tolerances of ±0.003mm. Mold flow analysis (e.g., Moldex3D) optimizes gate positions to minimize weld lines. For example, in IV drip chamber molds, a combination of fan gates and sub-gates shortens packing paths.

1.3 Full Lifecycle Material Management

-

Supplier Screening: Prioritize suppliers with ISO 10993 biocompatibility certification, demanding molecular weight distribution, additive lists, and pharmacopeia compliance (e.g., USP Class VI).

-

Batch Control: Each material batch undergoes Karl Fischer titration for moisture content (≤0.02%) and trial molding to verify shrinkage stability. For instance, a medical-grade COC material’s narrow molecular weight distribution enhances melt strength by 30%, reducing short shots in thin-wall injection.

2. Critical Defect Types and Prevention Strategies

2.1 Flash (Burr)

Phenomenon: Plastic overflow at parting lines or slider interfaces, risking packaging damage or debris generation.

Causes:

-

Insufficient clamping force (e.g., clamping force < injection pressure × cavity projected area × 1.1).

-

Worn parting surfaces or clogged vent slots.

Solutions:

-

Mold design optimization: Use nitrogen gas springs for auxiliary clamping and increase parting surface hardness (HRC ≥50).

-

Process adjustment: Reduce injection speed to 30–50mm/s and implement staged packing (e.g., 80% injection pressure for 10s, then 50% for 5s).

Case Study: A syringe barrel manufacturer reduced flash rates by 92% by improving parting surface precision from 0.02mm to 0.005mm.

2.2 Sink Marks

Phenomenon: Depressions at thickness transitions (e.g., rib backs), affecting transparency and strength.

Causes:

-

Inadequate packing pressure or duration.

-

Mismatch between mold temperature and melt temperature (e.g., crystalline PE mold temperature <60°C).

Solutions:

-

Staged packing: Apply “high-pressure–low-pressure” packing (e.g., 80% injection pressure for 15s, then 50% for 5s).

-

Mold temperature control: Use zone-controlled mold temperature machines to maintain temperature differences ≤±1°C in regions with thickness variations >0.3mm.

Case Study: A polypropylene medicine bottle manufacturer reduced sink mark depth by 0.15mm and improved filling accuracy to 99.8% by raising mold temperature from 50°C to 70°C.

2.3 Weld Lines

Phenomenon: Linear marks at melt front junctions, posing bacterial growth risks.

Causes:

-

Insufficient gate quantity or poor placement.

-

Low injection speed (<10mm/s) causing melt front cooling.

Solutions:

-

Gate optimization: Use hot runner systems with multi-point gating (e.g., 4 pinpoint gates for hemodialyzer housings, improving weld line strength by 40%).

-

Process adjustment: Increase injection speed to 80–100mm/s and raise barrel temperature to material melting point +20°C (e.g., PC from 280°C to 300°C).

Case Study: A blood collection tube manufacturer relocated weld lines to non-visible areas, boosting pass rates from 85% to 98%.

2.4 Chemical Stability Risks

Phenomenon: Material reactions with drugs or disinfectants, causing swelling or harmful substance release.

Causes:

-

Improper material selection (e.g., ordinary PP swelling >5% in ethanol).

-

Excessive additives (e.g., DEHP plasticizer content >0.1%).

Solutions:

-

Material certification: Choose FDA 510(k)-approved specialty resins (e.g., UHMWPE for IV tubing, improving chemical resistance by 3×).

-

Process control: Strictly monitor drying conditions (e.g., COC dried at 100°C for 4 hours to prevent hydrolysis).

Case Study: A medicine bottle manufacturer achieved 100% drug compatibility test pass rates by switching from ordinary PC to COC.

3. Continuous Improvement and Digital Empowerment

3.1 SPC Statistical Process Control

Deploy real-time monitoring systems to analyze fluctuations in critical parameters (e.g., injection pressure, mold temperature). Set upper control limits (UCL) and lower control limits (LCL). For example, an enterprise reduced dimensional tolerance variations from ±0.05mm to ±0.02mm using SPC, cutting annual rework costs by $280,000.

3.2 AI-Driven Defect Prediction

Leverage machine learning models to analyze historical production data and predict high-risk conditions. For instance, an enterprise shortened mold modification cycles from 2 weeks to 3 days using AI-predicted weld line locations, accelerating new product development by 40%.

3.3 Closed-Loop Quality Traceability

Establish a full-chain traceability system from raw material batches to finished product serial numbers, enabling rapid root-cause analysis. For example, an enterprise resolved defect origins within 2 hours using QR code labels, reducing customer complaint response times by 75%.

Conclusion

Quality control in medical injection molding must span design, materials, processes, and inspection. By constructing precision manufacturing systems, implementing defect prevention strategies, and driving digital transformation, enterprises can achieve zero-defect production, delivering safer, more reliable medical products globally.

Home

Home