In the dual drive of continuous upgrading in the healthcare industry and accelerating population aging, injection molding technology for medical products is undergoing a profound transformation from traditional manufacturing to intelligence, precision, and green production. As a core process in high-end medical device manufacturing, injection molding not only bears the responsibility of enhancing product performance and reducing production costs but also serves as a key force driving innovation in the medical sector. This article analyzes the future development paths and market prospects of medical product injection molding technology from three dimensions: technological trends, market demand, and competitive landscape.

I. Technological Trends: Intelligence, Miniaturization, and Green Production Lead Innovation

-

Intelligent Manufacturing: From "Labor-Dependent" to "Fully Automated"

With the deep integration of AI, IoT, and industrial internet technologies, injection molding production is moving toward "dark factories." For example, Xinmao Injection Molding has achieved full-process automation in mold opening/closing, injection, cooling, and demolding by introducing automated robots and intelligent quality inspection systems, boosting production efficiency by over 40% and reducing product defect rates to below 0.5%. In the future, AI algorithms will further penetrate into process parameter optimization, predictive maintenance, and equipment health management, enabling real-time analysis of vibration, temperature, and pressure data for adaptive production adjustments, significantly reducing manual intervention and energy consumption costs.

-

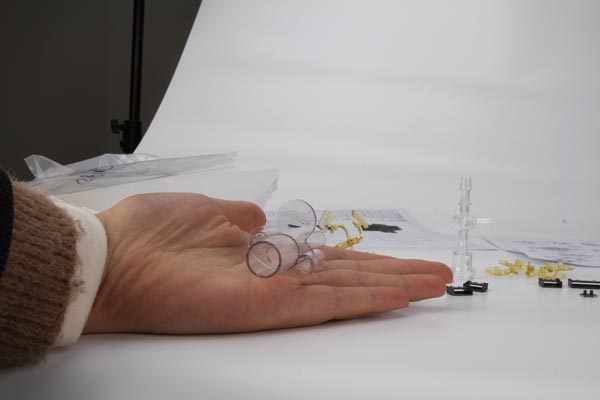

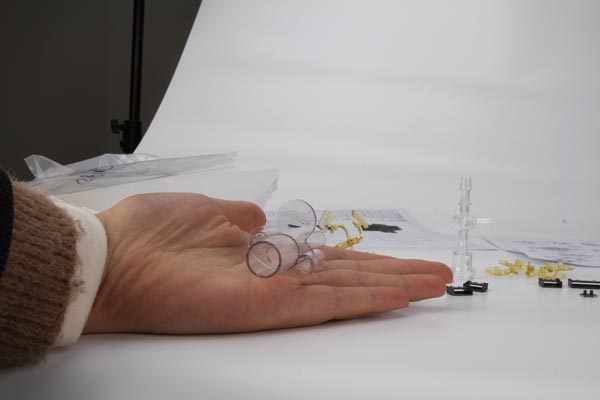

Miniaturization and Precision: Meeting Personalized Medical Needs

As minimally invasive surgeries, wearable devices, and smart implants become widespread, medical products demand injection molding precision beyond the micrometer level. For instance, cardiac stents and neurostimulators require high-precision micro-injection molding to achieve one-step molding of complex structures while ensuring functionality and biocompatibility. Meanwhile, multi-component co-injection molding and in-mold decoration (IMD) processes enable multi-material composites and customizable colors, catering to personalized medical scenarios. By 2030, the global market for micro-injection molded medical products is projected to exceed $12 billion, with a CAGR of 15%.

-

Green Transformation: Biobased Materials and Circular Economy Dominate

Stricter environmental regulations and sustainability principles are driving the medical injection molding industry toward green production. On one hand, the adoption of biobased biodegradable materials (e.g., PLA, PHA) is rising rapidly, expected to account for over 35% of the medical plastics market by 2026, replacing traditional non-degradable materials like PVC and PE. On the other hand, circular economy models—through recycling of packaging materials and resource recovery of production waste—maximize resource efficiency. For example, China’s medical plastic packaging industry has achieved an 85% recycling rate for waste, reducing carbon emissions per unit by 20%, with green packaging material usage projected to surpass 60% by 2026.

II. Market Demand: Population Aging and Technological Innovation Drive Growth

-

Global Market Expansion Continues

According to MarketsandMarkets, the global market for plastic injection molding in medical devices will reach 48.7 billion by 2025, with injection molding accounting for over 68 billion, with a CAGR of 12.3%. Key drivers include:

-

Population Aging: The global share of people aged 60+ will rise from 12% in 2015 to 22% by 2050, fueling demand for chronic disease management and high-precision injection molded products like cardiovascular devices and orthopedic implants.

-

Technological Innovation: Emerging technologies such as 3D printing, biocompatible materials, and smart drug delivery systems are accelerating adoption, creating new application scenarios for injection molding.

-

Policy Support: China’s "14th Five-Year Plan" for medical devices and the U.S. "Buy American" policy encourage domestic innovation and localization, boosting collaborative development of the injection molding supply chain.

-

High-Potential Submarkets

-

Cardiovascular Devices: Heart stents, catheters, and pacemakers demand ultra-high precision and biocompatibility, with a projected market share exceeding 30% by 2026.

-

Minimally Invasive Surgical Instruments: Laparoscopes and endoscopes are driving rapid growth in micro-injection molding.

-

Wearable Medical Devices: Smart bands and glucose monitors require lightweight, waterproof designs via injection molding, with a CAGR of 18%.

-

Drug Delivery Systems: Smart syringes and microneedle patches rely on injection molding for complex structures and mass production.

III. Competitive Landscape: High Technical Barriers and Regional Clustering

-

Global Market Features a "Bipolar Pattern"

-

North America Leads High-End Markets: Leveraging advanced healthcare infrastructure, strong R&D capabilities, and local manufacturing (e.g., Abbott, Medtronic, Jabil), North America holds over 40% of the global medical plastics market, particularly in biocompatible materials and smart injection molding equipment.

-

Asia-Pacific Accelerates Rise: China and India are emerging as growth engines due to cost advantages, policy support, and complete supply chains. China’s medical device market is projected to exceed ¥2.5 trillion by 2030, with injection molding component demand growing faster than the industry average. The Yangtze River Delta and Pearl River Delta regions have formed complete industrial clusters.

-

Enterprise Competition Focuses on Three Capabilities

-

Technical R&D: Firms mastering high-precision micro-injection molding, multi-component co-injection, and cleanroom automation (e.g., Tongda Medical, Mindray’s supply chain partners) dominate premium markets.

-

Compliance and Certification: ISO 13485, FDA/CE registration, and biocompatibility testing are essential for market entry, with compliance costs exceeding 15% of total expenses.

-

Supply Chain Integration: Efficiency across raw material suppliers (e.g., Wanhua Chemical, Hengli Petrochemical), midstream manufacturers (e.g., Xinmao Injection Molding), and downstream applications (hospitals, clinics) determines competitiveness.

IV. Future Outlook: Bidirectional Growth of Technology and Market Expansion

Over the next five years, medical product injection molding technology will see three key trends:

-

Deeper Technological Integration: AI, 5G, and digital twins will merge with injection molding for transparent, traceable, and intelligent production.

-

Accelerated Material Innovation: Biobased materials, nanocomposites, and smart-responsive materials will drive breakthroughs in product performance and functionality.

-

Global Market Expansion: Chinese injection molding machine firms will shift from "product exports" to "brand and ecosystem exports," establishing overseas R&D centers and offering localized solutions to capture global market share.

Conclusion: Driven by healthcare demand upgrades and technological revolutions, injection molding technology for medical products is entering a golden era. Firms must prioritize technological innovation, compliance, and green production while leveraging supply chain collaboration to seize opportunities in global healthcare supply chain restructuring and achieve sustainable growth.

Home

Home