In the field of medical injection molding, the hygiene and durability of plastic materials are crucial factors for ensuring the safety and effective operation of medical devices. These two characteristics permeate the entire life cycle of medical device design, production, use, and maintenance, having a profound impact on patient health and medical quality.

Manifestations of Hygiene

Biocompatibility

Biocompatibility is the core requirement for the hygiene of medical plastic materials. It demands that the material does not trigger toxic, harmful, or immunogenic reactions when in contact with human tissues or body fluids. For example, when producing injection-molded containers for cell culture, medical-grade plastics that have undergone rigorous biosafety testing are selected to ensure they do not interfere with the normal growth and metabolism of cells. Polycarbonate (PC), with its good biocompatibility, is widely used in the manufacture of dialyzers, incubators, and surgical tools. When in contact with the human body, it does not cause toxicity or damage to tissues and organs, ensuring the safety of the medical process.

Chemical Stability

Medical plastic materials need to possess excellent chemical stability to prevent the components of the material from leaching into drugs or the human body. For instance, polyvinyl chloride (PVC) is one of the more widely used medical plastics, often used in the manufacture of liquid containers, blood bags, and pipelines. Under normal use, PVC can maintain chemical stability and does not release harmful substances into the liquids or the human body it contacts. However, to make PVC flexible, plasticizers such as di(2-ethylhexyl) phthalate (DEHP) are sometimes added. Studies have found that DEHP may leach from medical products and enter the patient's body, posing potential health risks to newborns, pediatric ICU patients, etc. This highlights the importance of selecting appropriate plastic materials and additives to ensure chemical stability.

Sterilization Adaptability

Medical devices require strict sterilization to prevent the spread of infections, which means that plastic materials must be able to withstand frequent sterilization methods such as high temperatures, radiation, steam, and chemicals. Polypropylene (PP) is a thermoplastic with high-temperature and chemical resistance. It has a high melting point and can be disinfected and sterilized at temperatures above 100°C, making it very suitable for manufacturing syringes, casings, vials, and other medical devices that require repeated sterilization. Polyether ether ketone (PEEK), as an advanced thermoplastic, has excellent chemical resistance and thermal stability and can be used in the manufacture of high-performance medical applications such as trauma implants and spinal fusion cages. It maintains stable performance under complex sterilization environments.

Low Leachables and Extractables

Medical plastic materials should ensure that the levels of leachables and extractables are below dangerous levels to avoid adverse reactions caused by these substances entering the human body. During the production process, strict screening and testing of raw materials are required to ensure they comply with relevant standards. For example, when manufacturing medical devices that come into contact with blood, hemolysis tests must be conducted to ensure that the plastic does not induce thrombus formation, embolism, red blood cell rupture, etc., thereby safeguarding the patient's circulatory system.

Manifestations of Durability

Physical Properties

-

High Strength and Stiffness: Medical injection-molded parts may need to withstand certain external forces during use, so they require sufficient strength and stiffness. For example, ultra-high molecular weight polyethylene (UHMWPE) has high impact strength and energy absorption characteristics, making it an ideal material for artificial hip, knee, and shoulder joints. It can withstand the movement pressure of the human body over a long period without damage.

-

Creep Resistance: Some medical components such as plastic tubes and equipment casings are repeatedly bent, which requires the material to have good creep resistance to prevent deformation due to long-term stress during use. By controlling process conditions such as the material temperature and mold temperature during the molding process of polyethylene (PE), its crystallinity can be increased, thereby enhancing its creep resistance and ensuring the dimensional stability of pipelines and other components during long-term use.

-

Impact Resistance and Wear Resistance: The external components of medical devices may be subject to collisions and scratches during daily use, so they need to have good impact resistance and wear resistance. Polycarbonate (PC) has high impact resistance and is often used in the manufacture of surgical tools, orthodontic appliances, and lenses. It is not prone to breakage when subjected to external impact, and its wear resistance also ensures the appearance and performance of these devices over a long period of use.

Chemical Properties

-

Chemical Corrosion Resistance: Medical injection-molded parts may come into contact with various chemical reagents such as disinfectants and drugs, so they need to have chemical corrosion resistance. Polypropylene (PP) has good tolerance to many chemical substances and can resist the erosion of common acids and alkalis. In biochemical experiments, it is used to manufacture injection-molded bottles for holding various reagents, which do not deform, break, or experience performance degradation after long-term use.

-

Aging Resistance: Medical injection-molded parts need to be used for a long time under certain environmental conditions, so they require good aging resistance. Medical-grade PC plastic can maintain its physical and chemical properties for a long time under normal medical environmental temperatures. However, when exposed to high temperatures for a long time or in contact with strong oxidizing chemicals, its molecular chains may gradually undergo thermal degradation or chemical aging, leading to a decrease in mechanical properties. Therefore, when designing medical devices, appropriate plastic materials should be selected according to the use environment, and corresponding protective measures such as adding ultraviolet absorbers should be taken to improve their aging resistance.

Process Properties

-

Injection Molding Process Adaptability: Different plastic materials have different injection molding process characteristics. Selecting suitable materials can ensure the smooth progress of the injection molding process and the quality of the injection-molded parts. For example, polyethylene (PE) has a wide processing temperature range, is not prone to decomposition, and has moderate fluidity. During the injection molding process, it can better fill the mold cavity and produce injection-molded parts with high dimensional accuracy. Polymethyl methacrylate (PMMA) has a high melting point and requires precise temperature control during injection molding to avoid internal stress concentration caused by uneven temperature, thereby improving the durability of the injection-molded parts.

-

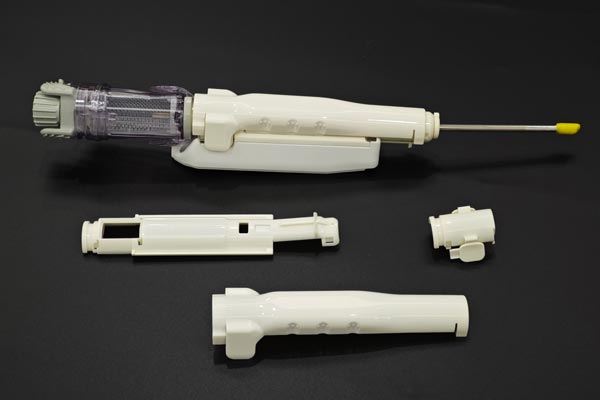

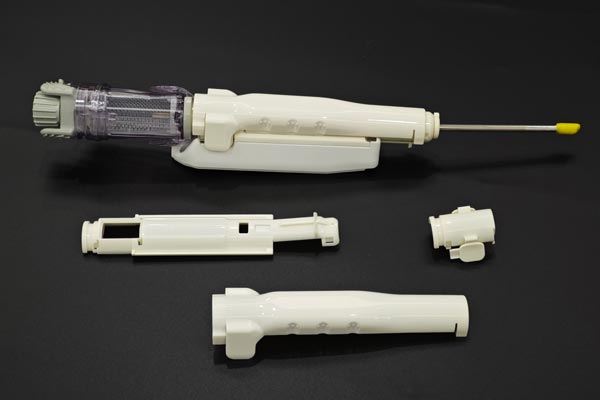

Secondary Molding and Surface Treatment Processes: To improve the durability of medical injection-molded parts, special processes such as secondary molding and surface treatment can also be used. For example, secondary molding treatment of some injection-molded parts can enhance the bonding strength between components by performing secondary injection molding on specific parts on the basis of the initial molding, ensuring that the different functional parts of medical devices with complex structures are tightly combined and not prone to separation or loosening. Surface treatment processes such as coating on the surface of injection-molded parts can enhance their wear resistance and corrosion resistance, enabling them to maintain good performance in harsh environments.

In medical injection molding, the hygiene and durability of plastic materials are manifested in multiple aspects. These characteristics are interrelated and influence each other, jointly ensuring the quality and safety of medical devices. With the continuous development of the medical industry, higher requirements are placed on the hygiene and durability of plastic materials, necessitating continuous research and development and improvement of materials and optimization of production processes to meet the growing medical needs.

Home

Home