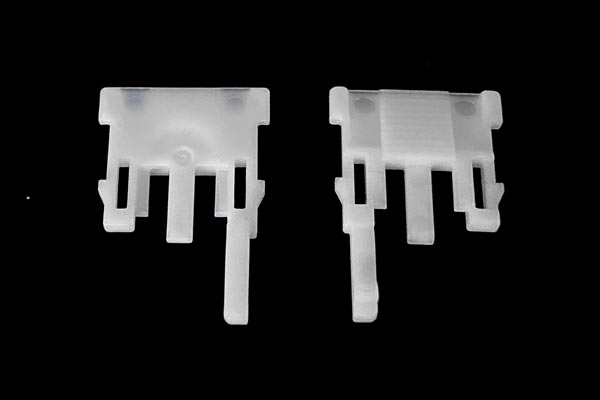

In the medical field, injection-molded parts serve as crucial components of numerous medical devices, and their quality directly relates to the health and safety of patients. Aseptic and dust-free conditions are not only basic requirements for medical injection-molded parts but also the core elements to ensure the smooth progress of medical procedures and avoid infection risks. Achieving aseptic and dust-free production of medical injection-molded parts requires comprehensive control across multiple aspects, including the production environment, raw materials, production processes, personnel management, as well as packaging and transportation.

Stringent Production Environment: The Foundation of Aseptic and Dust-Free Conditions

The production of medical injection-molded parts must take place in a highly clean environment, with cleanrooms being the key facilities. These cleanrooms are typically designed and constructed according to strict cleanliness standards. Through an efficient air purification system, they continuously filter out dust particles, microorganisms, and other pollutants in the air, ensuring that the air cleanliness inside the cleanroom reaches the corresponding level, such as Class 100 or Class 1000. Meanwhile, parameters like temperature, humidity, and pressure within the cleanroom need to be precisely controlled to maintain a stable production environment and prevent fluctuations from affecting product quality.

To further reduce the risk of contamination, cleanrooms adopt a sealed design and are equipped with airtight doors, pass boxes, and other facilities to prevent the entry of external pollutants. The equipment and tools inside the cleanroom also require regular cleaning and disinfection to ensure that their surfaces are free from dust, oil stains, and microbial growth. In addition, the movement of personnel and the transportation of materials within the cleanroom need to be strictly managed. Dedicated personnel and material passages are set up, along with corresponding purification measures, such as personnel changing clothes, washing hands, and air showers, as well as material cleaning and disinfection, to prevent personnel and materials from bringing pollutants into the cleanroom.

High-Quality Raw Materials: The Source Guarantee for Aseptic and Dust-Free Conditions

The quality of raw materials directly impacts the quality of medical injection-molded parts. Raw materials used for producing medical injection-molded parts must comply with strict medical standards, possessing good biocompatibility, chemical stability, and physical properties. When selecting raw materials, it is essential to ensure that their sources are reliable and that suppliers have a well-established quality management system and a good reputation.

Before entering the production cleanroom, raw materials need to undergo strict inspection and pre-treatment. The inspection covers aspects such as appearance, dimensions, and performance to ensure that the raw materials meet quality requirements. Pre-treatment includes steps like cleaning and drying to remove dust, oil stains, and moisture on the surface of the raw materials, preventing these impurities from affecting product quality during the injection molding process. For some raw materials with extremely high aseptic requirements, sterilization treatment is also necessary, such as using ethylene oxide sterilization or radiation sterilization methods to ensure that the raw materials are sterile.

Refined Production Processes: The Key Link for Aseptic and Dust-Free Conditions

The injection molding process is the core part of producing medical injection-molded parts, and the control of process parameters is crucial for the aseptic and dust-free nature of the products. During the injection molding process, parameters such as injection speed, pressure, and temperature need to be precisely controlled to ensure that the plastic melt fully fills the mold cavity, avoiding defects like air bubbles and shrinkage cavities. These defects not only affect the appearance and performance of the products but may also serve as breeding grounds for microorganisms.

The design and manufacturing of molds also have a significant impact on the aseptic and dust-free nature of the products. Molds should have good sealing and venting properties to prevent the leakage of the plastic melt and the generation of gases during the injection process, thereby reducing the production of pollutants. At the same time, the surface of the mold should be smooth and flat, making it easy to clean and disinfect to avoid the residue of plastic fragments, oil stains, and other impurities on the mold surface, which could affect product quality.

During the production process, it is also necessary to regularly clean and maintain the equipment and molds, and promptly replace worn parts to ensure the normal operation of the equipment and molds. In addition, strict control should be exercised over impurity contamination during the production process, such as using filtration devices to filter out impurities in the plastic melt and prevent impurities from entering the product interior.

Standardized Personnel Management: An Important Support for Aseptic and Dust-Free Conditions

Personnel are the most active factor in the production process and also a key link in pollution control. Personnel entering the cleanroom must undergo strict training to master the relevant knowledge and skills of aseptic and dust-free production, be familiar with the rules and regulations and operating procedures of the cleanroom. Before entering the cleanroom, personnel need to follow the prescribed procedures for changing clothes, washing hands, and air showers, and wear protective equipment such as cleanroom suits, masks, and gloves that meet the requirements to prevent human shedding and microbial contamination of the products.

During the production process, personnel should strictly abide by the operating procedures, avoid unnecessary movements and contacts, and reduce the production and spread of pollutants. At the same time, regular health checks should be conducted on personnel to ensure that they are in good health and free from infectious diseases, preventing personnel from bringing pathogens into the cleanroom. In addition, regular training and assessment should be carried out on personnel to continuously improve their quality awareness and operating skills, ensuring the effective implementation of aseptic and dust-free production.

Reliable Packaging and Transportation: The Final Guarantee for Aseptic and Dust-Free Conditions

After the production of medical injection-molded parts is completed, reliable packaging is required to prevent the products from being contaminated during transportation and storage. Packaging materials should have good sealing, barrier, and aseptic properties, effectively preventing the entry of dust, microorganisms, and other pollutants into the packaging. Commonly used packaging materials include sterile bags, paper-plastic composite bags, and aluminum foil bags, which need to undergo strict sterilization treatment to ensure their sterility.

During the packaging process, operations should be carried out strictly in accordance with the operating procedures to avoid contamination of the products during packaging. After packaging is completed, the packaging should be inspected for sealing to ensure good sealing. During transportation, appropriate transportation tools and methods should be selected to prevent the products from being subjected to挤压 (should be "compression"), collision, and vibration. At the same time, parameters such as temperature and humidity in the transportation environment should be controlled to ensure the stable quality of the products during transportation.

Achieving aseptic and dust-free production of medical injection-molded parts is a systematic project that requires comprehensive and strict management and control across multiple links, including the production environment, raw materials, production processes, personnel management, and packaging and transportation. Only through the coordinated cooperation of all links can the quality of medical injection-molded parts meet medical standards and provide reliable protection for the health and safety of patients. As medical technology continues to advance and people's requirements for medical quality keep increasing, the aseptic and dust-free production of medical injection-molded parts will also face higher challenges and requirements, necessitating continuous exploration and innovation to drive the production technology of medical injection-molded parts to a higher level.

Home

Home